TB-9-2920-225-34-1 - Page 58 of 70

TB 9-2920-225-34-1

CHAPTER 4

LELAND AIRBORNE MODEL

4-1. Introduction.

One model was produced by

Leland Airborn Products Division of American

Machine and Foundry Co. The manufacturer’s

name is now:

CODE IDENT

07639 (FSCM)

Leland Electrosystems Inc.

740 E. National Road

P.O. B

OX

128

Vandalia, OH 45377

TELEPHONE

AC 513898-5881

The manufacturer is also now known as AMF

Electrosystems Division at the same address. The

manufacturer’s part number for this model is CSV

2183-1.

4-2. General Inspection.

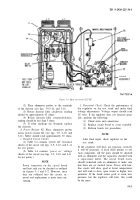

a. Regulator Box Assembly (external).

Check

for missing or stripped cover, connector and

mount retainer screws and voltage adjustment ac-

cess plug. Check connectors for signs of arcing,

bent or pushed in pins, broken connectors and

thread damage. Correct deficiencies by utilization

of serviceable components from unrepairables or

requisitioning components from the manufacturer.

The pin receptacle (J2) is part number 19207–

7064429 or MS3102A28–22P per MIL-C-5015.

The socket receptacle (Jl) is part number 19207-

7064706, for which there is no equivalent NSN

number.

As assembly is available from Bendix.

CODE IDENT

77820 (FSCM)

Bendix Corp. The

Components Div.

Sherman Avenue

Sidney, NY 13838

Electrical

It should be ordered as part number 60–42228–

10S, it is possible that extensive damage has been

done and the regulator cannot be easily repaired.

Components should be performance tested and re-

tained if acceptable. Check for disconnected or

burnt wires, missing components and replace/re-

pair as necessary. Carefully remove the transistor

mounting plate noting the position of the screws,

washers and rubber insulators. Visually inspect

the circuit board for burnt components. Replace

the circuit board through cannibalization if burnt

components are found. Carefully reinstall the

transistor mounting plate.

c. Regulator Verification Check.

After perform-

ing the regulator appears to be in good condition,

check its performance on a test stand.

If the regulator fails this check, proceed to para-

graph 4–3.

4-3. Bench Testing.

a. General.

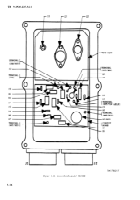

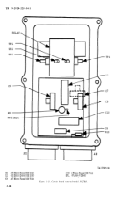

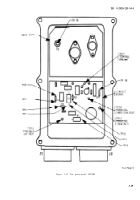

Figures 4-1 and 4-2 show the

method for testing NPN transistors. Figure 4-3

shows a plan view of the circuit board assembly,

the regulator with the cover and circuit board re-

moved, and an electrical schematic diagram of the

regulator.

b. Diode and Relay.

(1) Remove six screws and place the circuit

board to one side.

(2) Place positive probe of ohmmeter to pin

F of connector J2, (see fig. 4-3).

(3) Place negative probe to TP1. Meter

should indicate low resistance.

(4) Reverse probes. Meter should indicate

high resistance.

(5) If other readings are obtained, replace

diode CR6, (see fig. 4-3).

(6) Move negative probe to TP2. Meter

should read approximately 250 ohms.

(7) If another reading is obtained, replace

the relay, (see fig. 4–3).

c. Field Discharge Diode.

(1) Place positive probe of ohmmeter to pin

E of connector J1 (see fig. 4-3).

(2) Place negative probe to pin B of J1.

Meter should indicate low resistance.

(3) Reverse the probes. Meter should indi-

cate high resistance.

(4) If other readings are obtained, replace

diode CR7.

4-1

Back to Top