TM-5-3805-254-14-P-2 - Page 131 of 894

TRUCK SERVICE MANUAL

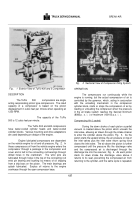

BREAKS-AIR

Removing and Disassembling Cylinder Head

Remove capscrews or nuts from studs attaching

cylinder head and lift off cylinder head.

’he cylinder may have to be tapped with a raw hide

hammer to break gasket joint.

Remove cylinder head gasket and scrape off any gasket

material that may remain on cylinder head and block.

Remove discharge valve cap nuts and lift out discharge

valve springs and discharge valves.

Removing and Disassembling Piston and

Connecting Rod Assemblies

Straighten prongs of connecting rod bolts and

remove bolts and bearing caps.

Then push pistons with

connecting rods attached out the top of the cylinder

block.

Replace caps on each connecting rod to avoid

damage to bearings.

Connecting rod caps and

connecting rods are already marked with center punch

marks to show the proper position of the caps on the

rods.

Remove piston rings from each piston.

If pistons

are to be removed from connecting rods, remove wrist

pin lock wires from wrist pins and press pins from pistons

and connecting rods.

Removing Crankshaft

Remove capscrews or nuts from studs, securing

end cover to crankcase at drive end of crankshaft.

Remove end cover with oil seal and gasket.

If oil

seal needs replacing, remove it from end cover.

Remove capscrews or nuts from studs, holding opposite

end cover to crankcase.

Remove end cover and gasket.

Some crankcases are fitted with a shoulder to

position the crankshaft in the crankcase.

In such cases

the crankshaft may be removed only through one end of

the crankcase.

Press crankshaft and ball bearings out of

crankcase.

Removing Cylinder Block

When cylinder head is removed from cylinder

block, the inlet valve springs and inlet valves should be

removed.

If compressor is fitted with an air strainer, remove

screws and lock washers securing air strainer in place

and remove air strainer and air strainer gasket.

If compressor has a Type D or D2 governor

mounted on cylinder block, remove governor and gasket.

Remove capscrews or nuts securing cylinder block to

crankcase and remove cylinder block and cylinder block

gasket.

Remove unloader spring and unloader spring

seat.

Remove unloader spring saddle, unloader plunger

and unloader pistons.

Remove unloader piston

grommets.

Remove inlet valve seat bushings only if

seats are worn or damaged.

CLEANING AND INSPECTION OF PARTS

Clean all parts using cleaning solvent to remove all

traces of dirt, oil and grease before inspection.

Cylinder Head and Components

Put cylinder head body through a cleaning solution

to remove all carbon from discharge valve cavities and to

remove all rust and scale from water cavities.

Use air

pressure to blow dirt out of all cavities.

Scrape carbon,

dirt, and particles of old gaskets from all surfaces.

Clean discharge valves not damaged or worn

excessively by lapping them on a piece of crocus cloth

on a flat surface.

Oil Passages

Clean thoroughly all oil passages through

crankshaft, connecting rods, crankcase and end covers.

If necessary, probe oil passages with wire and flush with

cleaning solvent.

Cylinder Block

Put cylinder block through a cleaning solution to

remove all carbon and dirt from inlet passages and

unloader passages so as to remove rust and scale from

water cavity.

Clean inlet valves that are not damaged or worn

excessively by lapping them on a piece of crocus cloth

on a flat surface.

Scrape particles of old gaskets from all surfaces.

129

Back to Top