TM-5-3805-254-14-P-2 - Page 134 of 894

BREAKS-AIR

TRUCK SERVICE MANUAL

To test for leakage, apply 100 p.

s.

i.

air pressure

through the discharge port of the cylinder head and apply

soap suds to the discharge valve openings in the floor of

the cylinder head.

Leakage should not exceed a one

inch soap bubble in not less than five seconds.

If excessive leakage is found, leave the air

pressure applied and using a fiber or hardwood dowel

and light hammer, tap the discharge valves off their

seats several times to improve the seal between the

valves and their seats.

If the valves and valve seats

have been reconditioned properly, this will reduce the

leakage.

Leakage tests must also be made by applying

soap suds around the discharge valve cap nuts with air

pressure applied as above.

Leakage at cap nuts is not

permissible.

Inlet Valves and Seats

If inlet valve seats show signs of slight scratches

or wear, they can be reclaimed by using a lapping stone

and grinding compound.

If the seats cannot be

reclaimed in this manner, they should be replaced.

Install new inlet valve seats by pressing them into

cylinder block to dimensions shown in the specifications.

Inlet valves not worn excessively or damaged can

be reclaimed by lapping them on a piece of crocus cloth

on a flat surface.

REASSEMBLY

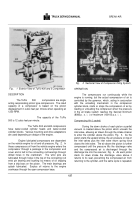

Installing Cylinder Block

Place new cylinder block gasket in position on

crankcase studs.

Position cylinder block on crankcase in

accordance with markings made before disassembly.

Install nuts and lock washers securing cylinder block to

crankcase.

Installing Cranks haft

If the crankshaft is fitted with oil seal rings, install

rings.

Position ball bearings and crankshaft in

crankcase, being sure the drive end of the crankshaft is

positioned as marked before disassembly.

If one end of

the crankcase is counter bored for holding bearing, be

sure the crankshaft is installed through the correct end of

the crankcase.

Carefully press crankshaft and bearings

into crankcase using arbor press.

Place a new rear end cover gasket in position over

studs on rear end of crankcase being

¾ sure the oil

hole in the gasket lines up with the oil hole in the

crankcase.

If end cover includes an oil seal ring, install

oil ring.

Position end cover over studs in crankcase

being sure oil holes in end cover line up with oil

A

holes in gasket and crankcase.

Install capscrews or nuts

securing end cover in place.

Install pipe plugs in end cover oil openings which are not

in use.

If opposite end cover includes an oil seal and the

seal has been removed, press a new seal in the end

cover.

Install a new end cover gasket.

Carefully position

the end cover to avoid damage to oil seal and install

capscrews or nuts securing end cover in place, Fig.

9.

Back to Top