TM-5-3805-254-14-P-2 - Page 132 of 894

BREAKS-AIR

TRUCK SERVICE MANUAL

Air Strainer

Wash curled hair from air strainer in cleaning

solution and then saturate it with clean oil, squeezing out

excess oil before replacing it in air strainer.

Ball Bearings

All ball bearings must be cleaned thoroughly in

cleaning solvent.

INSPECTION OF PARTS

Cylinder Head Body

I

Inspect cylinder head body for cracks or breaks.

Replace if any defects are found.

Water Passages

Test water jacket of cylinder head and cylinder

block for leakage, using air pressure.

Replace unit if

leakage is found.

Discharge Valve Springs

Discard all used discharge valve springs and

replace with new springs.

Discharge Valves and Seats

Inspect condition of discharge valves and

discharge valve seats.

If discharge valves are grooved

deeper than .

003" where they contact the seats, they

should be replaced.

If the discharge valve seats are

worn excessively so there is no longer sufficient metal

left to reclaim the seat by using a lapping stone, the

seats should be replaced.

Crankcase and End Covers

Check crankcase and end covers for cracks and

broken lugs.

Replace if any damage is found.

End Covers

If an oil seal ring is used in the end cover, check fit

of ring in the ring groove and have .008" to .015"

clearance at the gap when placed in the end bore of the

crankshaft.

Check oil seal ring for wear.

If worn thin or

damaged, the oil seal ring must be replaced.

Inspect oil

ring groove in end cover.

If ring wear has formed a step

pattern in groove, replace end cover or machine groove

for

next

oversize

oil

seal

ring.

Crankcase Bearing Bores

Check fit of ball bearings in crankcase. Bearings

must be a finger press fit.

If crank-case bearing bores

are worn or damaged, the crankcase should be replaced.

Cylinder Block Check for cracks or broken lugs on

cylinder block.

Also check unloader bore bushings to be

sure they are not worn, rusted or damaged.

If these

bushings are to be replaced, they can be removed by

running a 1/8" pipe thread tap inside the bushing, then

inserting a 1/8" pipe threaded rod and pulling the bushing

straight up and out.

Do not use an easy-out for removing

these bushings.

Inlet Valve and Seats

Inspect condition of inlet valves and seats.

If inlet valves are grooved deeper than .003" where they

contact the seat, they should be replaced.

If the inlet

valve seats are worn or damaged so that they cannot be

reclaimed by facing or lapping, seats should be replaced.

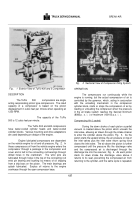

Cylinder Bores

Check cylinder bores for evidence of excessive

wear, out of round, or scoring.

Cylinder bores which are

scored or out of round more than .

002", Fig.

6, or

tapered more than .

003", as should be re-bored or

honed oversize.

Oversize pistons are available in .010",

.020" or.

030" oversize.

Cylinder bores must be smooth,

straight and round.

Refer to specifications for proper

clearance between piston and cylinder bore.

Aluminum

pistons are cam ground.

Back to Top