TM-5-3805-254-14-P-2 - Page 142 of 894

BRAKES-AIR

TRUCK SERVICE MANUAL

With the engine still running make a series of

brake applications to reduce the air pressure and

observe at which pressure the governor cuts in the

compressor.

As in the case of the cutout pressure, the

cut-in pressure should be in accordance with the

governor piece number. Common cut-in pressures vary

between 80100 psi.

Never condemn or adjust the

governor pressure settings unless they are checked with

an accurate test gauge or a dash gauge that is

registering accurately. If the pressure settings of the

governor are inaccurate or it is necessary that they be

changed, procedure is as follows.

First, unscrew the cover at the top of the governor.

Next, loosen the adjusting screw lock nut.

With a

screwdriver

the

adjusting

screw

is

turned

counterclockwise to raise the pressure setting and the

screw is turned clockwise to lower the pressure setting.

After the adjustment is completed, the adjusting screw

lock nut should be tightened to lock this adjustment.

Leakage Tests

Leakage checks on the D2 governor are made at

its exhaust port in both cut-in and cutout positions. In the

cut-in position check exhaust port for inlet valve leakage

by applying a soap solution at the port.

Leakage could

also be past the bottom piston grommet. In the cutout

position check the exhaust port to determine leakage at

the exhaust valve seat or stem grommet.

In this position

leakage could also be past the upper piston grommet.

Leakage in excess of a 1" soap bubble in 3

seconds is not permissible in either of the foregoing

tests.

If excess leakage is found, the governor must be

repaired or replaced.

REMOVE

Block and hold vehicle by means other than air

brakes.

Drain air brake system.

If

governor

is

compressor

mounted

type,

disconnect reservoir air line.

If remote mounted

governor, disconnect both the unloader and reservoir air

lines.

Remove governor mounting bolts, then governor.

INSTALL

If compressor mounted type governor, clean

mounting pad on both compressor and governor block.

Clean connecting line or lines.

Also be sure compressor

unloading port is clear and clean.

If the governor is being mounted remotely, it

should be positioned so that its exhaust port points

down. It should be mounted higher than the compressor

so that its connecting lines will drain away from the

governor.

Install governor.

If compressor-mounted type, use a new governor

mounting gasket.

Connect air lines to governor.

Test governor as

outlined under SERVICE CHECKS.

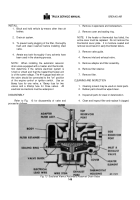

DISASSEMBLY

Clean governor exterior of road dirt and grease

using a good cleaning solvent and brush.

Unscrew the top cover.

With a pair of retaining ring pliers remove the

spring assembly retaining ring.

Remove the adjusting screw and spring assembly.

Remove the lock nut, then the hex-shaped upper

spring seat from the adjusting screw.

Remove the pressure setting spring, lower spring

seat, spring guide and the other lower spring seat from

the adjusting screw.

Remove the exhaust stem and its spring from the

top of the piston.

With the body in the inverted position tap it lightly

and the piston should fall out.

Remove the inlet and exhaust valve spring and the

valve from the piston.

Remove the two piston grommets and with a

hooked wire remove the exhaust stem grommet.

Clean or remove the unloader and reservoir port

filters.

CLEANING AND INSPECTION

Clean all metal parts in a good cleaning solvent.

Wipe rubber parts dry.

Inspect body for cracks or other damage.

Be

particularly careful that the body air passages, the filters,

exhaust stem and piston are not obstructed.

Check springs for cracks, distortion or corrosion.

Replace all parts not considered serviceable

during these inspections.

140

Back to Top