TM-5-3805-254-14-P-2 - Page 145 of 894

BRAKES-AIR

TRUCK SERVICE MANUAL

SERVICE CHECKS

1

.

With air brake system charged, test with soap

suds for leakage past the key.

Also check for

leakage through the body by coating the outside

of the drain cock with soap suds.

Leakage in

excess of a 3" soap bubble in 3 seconds is not

permissible.

2

.

Leakage is caused by dirty or scored key or

body.

Leakage due to dirt is corrected by

cleaning parts and applying a thin coating of Item

1 in LUBRICANT SPECIFICATIONS on the key.

Leakage due to a scored key or body cannot be

repaired and the drain cock must be replaced.

SAFETY VALVE

DESCRIPTION

The purpose of the safety valve is to protect the air

brake system against excessive air pressure.

Should the

air pressure in the air brake system rise above the

setting of the safety valve at 150 pounds, the valve

opens and permits pressure above 150 pounds to be

exhausted.

It is located on the supply reservoir.

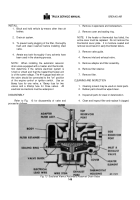

The safety valve is a piston type valve (Fig.

2).

The piston is equipped with an O ring type seal which

seats in the body of the valve.

Fig.

2

Sectional View of Piston Type Safety Valve

MAINTENANCE

Once each year or every 100,000 miles the safety

valve should be removed and thoroughly cleaned.

SERVICE CHECKS

Operating Test

The safety valve may be tested to be sure it is

operative by pulling the exposed end of the piston. This

removes the spring load from the piston and permits the

valve

to

exhaust.

Leakage Test

Leakage at the piston in the body should not

exceed a 3" soap bubble in 3 seconds.

If air leakage is

excessive the valve must be replaced since it is only

serviced as a complete component.

The safety valve should be set to "blow off" at

approximately 150 pounds.

The pressure setting may be

adjusted by turning the adjusting nut clockwise to raise

the pressure setting and turning the adjusting nut

counterclockwise to lower the pressure setting.

Since the safety valve must be removed to perform any

adjustments, it is suggested that the valve be replaced

when any defect is detected.

CAUTION: When replacing the safety valve be sure to

drain all air from the supply reservoir. Draining the

primary and secondary reservoirs are not required since

they are protected by check valves.

AIR PRESSURE GAUGE

DESCRIPTION

The purpose of the air pressure gauge is to

register the amount of reservoir air pressure in the air

system.

While air pressure gauges of this type are

commercially accurate, they must never be confused

with or substituted for test air gauges, which are intended

primarily for accurately checking air pressure in the air

brake system.

Back to Top