TM-5-3805-254-14-P-2 - Page 154 of 894

TRUCK SERVICE MANUAL

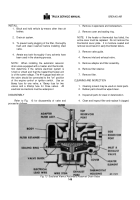

4. Remove screw (28) from body (1).

5. Remove piston assembly (18) and spring (16)

from body.

6. Remove snap ring (7), spring guide (8),

spring

(12), and shim washers (15).

7. Remove spring (16).

8. Remove "O"-ring (17) and vee-block seal (14).

9. Remove cap screws (22), lock washers (21),

end cap (24) and gasket (27).

10. Remove cage assembly and "O"-ring (20) from

body.

11. Hold exhaust valve (10), unscrew nut (26) and

remove exhaust valve spring (23) and inlet valve

(25) from cage assembly.

12. Remove snap ring (13), cap (10), air cleaner (9)

and screen (10A).

Inspection and Cleaning

1. Wash all metal parts in mineral spirits or

cleaning fluid.

2. Scrape old gasket material from mating surfaces

of end cap (24) and cage assembly.

3. Clean and wipe dry inlet valve (25) and exhaust

valve (19).

They must be replaced if nicked or

worn.

4. Examine inlet valve seat in cage assembly and

exhaust valve seat on piston (18).

They must be

free of nicks.

Crocus cloth may be used to

smooth off slight nicks; if nicks are too deep,

replace piston or cage.

5. Replace boot if cracked or deteriorated.

Assembly

1. Place spring (23) on stem of exhaust valve (19)

and install in cage with inlet valve (25) and nut

(26).

Tighten securely.

2. Install new "O"-ring (20) in body (1).

3. Use scratch marks to position gasket (27) and

cage

assembly,

install

lock

washers (21), cap

screws (22) and tighten securely.

4. Install new "O"-ring (17) and vee-block (14) on

piston (18).

5. Install shim washers (15) in piston (four normally

required) spring (12) shim washers (11) (two

normally required) and

secure in place with snap ring (7).

6. Apply light lubricant to inside bores of body.

Install piston assembly in body.

7. Install screw (28) with head of screw tight

against body.

8. Install plunger (6) in mounting plate (2),

position

mounting plate on body and secure in place with

three lock washers (3) and cap screws(4).

Tighten securely.

9. Install boot (5) in grooves in mounting plate.

NOTE:

The gap between the exhaust

valve and seat must be .06" minimum.

This may be checked by inserting a

feeler gauge through a delivery port.

Test

Released Position

Plug all cylinder ports.

Connect air supply and air

gauge to inlet port.

Check exhaust port with soapy

water.

No leakage allowed.

Applied Position

Connect air

supply

and air gauge to one cylinder

port.

Depress treadle or piston to allow 5 to 10 psi air

pressure to register on gauge in cylinder port.

Check

exhaust port with soapy water; a one inch soap bubble in

three seconds permissible.

Depress plunger of brake valve slowly so that brake

valve piston movement is also slight.

Note that pressure

gauge reading at cylinder port builds up in proportion to

pressure gauge reading at inlet port.

(The pressure

reading at cylinder port should become greater as

plunger is further depressed.) With plunger fully

depressed, both gauges should read alike.

While

plunger is depressed in this holding position, a one inch

soap bubble in three seconds at exhaust port is

permissible.

Coat the entire valve with soapy water especially

around gaskets, assembly screws,

and tubing fittings.

With brakes released or applied, no leaks are permitted.

If tightening the assembly screws or fittings does not

eliminate air loss, the brake valve must be disassembled

and reassembled correctly.

When tests determine that brake

valve

is

satisfactory, remove test gauges and air lines from valve.

Prevent the entrance of dirt in valve by plugging all ports

until valve can be reinstalled in air system.

152

BRAKES-AIR

Back to Top