TM-5-3805-254-14-P-2 - Page 158 of 894

TRUCK SERVICE MANUAL

SERVICE CHECKS

Operation Test

With two test gauges you know to be accurate,

disconnect one of the front brake chamber lines or

remove the plug from the unused brake chamber inlet

port, if this type, and install one of the test gauges.

The

other test gauge should be installed in a foot brake valve

delivery line.

Place the handle of the two-way valve in

the dry road position and make a foot valve application.

Readings on both test gauges should be the same.

Release the foot application and note that the air is

exhausted promptly at the exhaust port of the limiting

and quick release valve.

Place the handle of the two-way valve in the slippery

road position and apply the foot valve.

The reading on

the test gauge connected in the brake chamber or line

should be about one-half the reading on the test gauge

connected to the brake valve delivery line.

Leakage Test

With the two-way valve handle in the dry road

position, make and hold a foot valve application.

Check

the exhausts of both the two-way and limiting and quick

release valves for leakage.

Place the handle of the two-way valve in the slippery

road position.

Make a foot valve application and check

the exhaust of the two-way valve for leakage.

If the limiting and quick release valve or two-way

valve does not function as noted above or if leakage is

excessive, it is recommended that they be reconditioned

or replaced.

REMOVE AND REINSTALL.

Remove

To remove the limiting and quick release valve

assembly, disconnect all air lines at valve and remove

mounting bolts.

Install

Install valve in same location where removed using

same mounting bolts.

Connect brake chamber lines to

delivery ports of valve and brake valve delivery line to top

of inlet port and line from two-way valve to side inlet port.

The perform the tests listed in "SERVICE CHECKS".

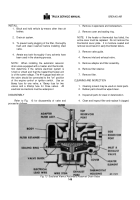

DISASSEMBLE

Remove the four capscrews that hold the valve cover

to the body.

Separate cover, gasket and body.

Push

piston assembly out of body.

If necessary, the piston

assembly can be dismantled and its component parts

serviced.

To disassemble the piston assembly, first

remove the piston grommets.

The boot type inlet and exhaust valves are

removable and serviceable.

They can either be cut or

pryed off the stem.

Remove the exhaust valve, valve guide and spring.

Pull the valve stem through the piston and remove

the inlet valve from its stem.

CLEANING AND INSPECTION

Clean all metal parts of both valves in good cleaning

solvent and dry thoroughly.

All rubber parts will be

replaced.

Check all metal seats for scratches or scores.

Polish seats with fine crocus cloth when they are nicked

or corroded.

Inspect all springs for cracks, distortion and

corrosion and replace where necessary.

REASSEMBLE

If an arbor press is available, the inlet and exhaust

valve boots should be pressed on the stem dry.

Without

an arbor press a little soap or water will make it easier to

press on the stem.

Install inlet valve boot on stem and insert in piston.

Position spring and valve guide over stem and press

exhaust valve boot on stem.

Lubricate body and cover bores, grommet and

grommet grooves and other areas of the piston with a

lubricant comparable to that listed in "LUBRICATION

SPECIFICATIONS" item 1.

Press piston assembly in body but with caution so

piston grommets are not damaged.

Position gasket and cover on body and install four

capscrews with lock washers.

156

BRAKES-AIR

Back to Top