TM-5-3805-254-14-P-2 - Page 160 of 894

TRUCK SERVICE MANUAL

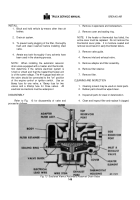

CLEANING AND INSPECTION

1. Wash all metal parts in mineral spirits or

cleaning fluid.

2. Inspect inlet valve seat in cage assembly.

It

must be smooth and free from nicks.

3. Inspect rubber face of inlet valve (22) and

exhaust valve (18).

Wipe clean.

Replace if

worn, nicked or distorted.

4. Inspect lower end of plunger (11), it must be

perfectly smooth.

5. Inspect two seals (6).

If they are worn,

press

out of body (1) and replace.

6. Scrape all traces of old gaskets (20) from mating

surfaces of cage assembly (21) and cap (23)

and body (1).

7. Orifice in body must be free of dirt.

ASSEMBLY

1. Install spring (19) on exhaust valve stem (18)

and install in body cage (21).

Apply inlet valve

(22), nut (24), and tighten securely.

2. Install new gaskets (20) on body cage.

Install

cage assembly in body (1) with five lock washers

(26) and cap screws (25).

Tighten securely.

3. Hold plunger (11) with threads facing upward,

install diaphragm (12) with bead facing down,

retainer plate (4) and tighten nut (16).

4. Apply light lubricant to outside of diaphragm and

plunger assembly (11) and install in body.

5. Install diaphragm (8), retainer (10) and screw (9)

in cap (7).

6. Locate cap on body and install three cap screws

(3) with lock washers (2).

Install five bolts and

apply lock washers (14) and nuts (15).

Tighten

all cover bolts securely.

7. Use thread protectors in all pipe ports to prevent

dirt entering the valve assembly.

TEST

1. Connect 100 psi air pressure to reservoir port.

2. Install air gauge in cylinder port.

No leak allowed

at exhaust port or around cage and cover

gaskets.

3. Apply pressure to service port.

No leak allowed

at exhaust port or at assembly bolts.

158

BRAKES-AIR

Back to Top