TM-5-3805-254-14-P-2 - Page 152 of 894

TRUCK SERVICE MANUAL

CHAPTER III

CHECK VALVES

ONE-WAY CHECK VALVE

DESCRIPTION

The one-way check valve (Fig.

1) is used to permit

passage of air pressure through the valve in one

direction only as indicated by the arrow on the side of the

valve.

They are installed in both primary and secondary

reservoirs to maintain the air supply in both reservoirs if

an air loss should occur ahead of the valve.

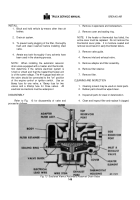

Fig. 1

Cross Sectional View of

One-Way Check Valve

Legend for Fig.

1

KeyDescription

1

BODY, Valve

2

SPRING

3

SEAL, Assembly

4

WASHER, Cap-to-Body

5

CAP, Valve

OPERATION

Air flow in direction of arrow moves the seal from its

seat and the air flow is unobstructed.

Flow in reverse

direction is prevented by seating of the seal by the

upstream air pressure and assistance of spring.

MAINTENANCE

Once each year or every 100, 000 miles check

operation (see SERVICE CHECKS).

SERVICE CHECKS

Depending upon installation, it may be easier or

necessary to completely remove check valve so that the

following checks may be made.

If

checking valves at primary and secondary reservoirs,

bleed air supply reservoir and disconnect air inlet to valve

and proceed as follows.

CAUTION:

Be sure to block or hold

vehicle to prevent it from moving.

With air pressure present at outlet side of check

valve and inlet open to atmosphere, use leak detector

tester to test for leakage.

A slight leakage is permitted.

However, if valve leaks excessively, the valve should be

replaced.

REMOVE

1. Block or hold vehicle by means other than air

brakes.

2. Drain all air reservoirs.

3. Disconnect air lines and remove check valve.

INSTALL

1. Check and, if required, clean or replace air line

to valve.

2. Install valve making certain that it is installed

correctly.

Arrow on outside of body indicates

direction of air flow through valve.

3. Check valve for leakage.

150

BRAKES-AIR

Back to Top