TM-5-3805-254-14-P-2 - Page 144 of 894

TRUCK SERVICE MANUAL

BRAKES-AIR

CHAPTER II

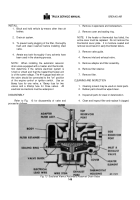

RESERVOIR DRAIN COCK SAFETY VALVE

PRESSURE GAUGE - LOW PRESSURE INDICATOR - STOP LIGHT SWITCH

RESERVOIR

DESCRIPTION

The air reservoir (air tank) function is to provide a

volume of compressed air used in braking the vehicle.

Another function of a reservoir is to provide a place

where the air, heated during compression, may cool and

cause the oil and water vapors to condense.

The combined volume of all service reservoirs and

supply reservoirs are 12 times the combined volume of

all service brake chambers at maximum travel of the

pistons or diaphragms.

The size of air tanks should

never be altered without IH Engineering approval.

The reservoirs should be completely drained daily.

If an automatic drain device is used, the automatic drain

should be checked periodically to determine if it is

functioning properly.

When manually draining tanks,

satisfactory draining is only accomplished by leaving the

drain cocks open after all air has escaped and all

drainage has stopped.

Reservoirs are tested against a 300 pound

pressure and treated on the inside with a rust preventive.

SERVICE CHECKS

1

.

Leakage Tests. With the air brake system

charged, use Leak Detector Tester (SE2326) to

check for leakage on outside surfaces of

reservoirs.

If any leakage is found, replace the

reservoir.

2

.

Inspection.

Inspect inside and outside surfaces

for damage or corrosion.

A small flashlight is

helpful when inspecting the interior.

If damage

or corrosion is found that would weaken the

reservoir, replace the reservoir.

3

.

Moisture taken in with the air through the

compressor inlet valve collects in the reservoirs

and necessitates draining the reservoirs daily in

cold weather and every week in warm weather

by opening the drain cock located on the bottom.

Be sure to close the drain cocks after all

moisture has been removed.

MAINTENANCE

Drain air reservoirs regularly as required.

Local conditions govern frequency.

In dry climates, for

example, once a month may be sufficient, while in humid

areas it may be necessary to drain reservoirs daily.

When draining the air reservoirs, open the drain

cock and let the air bleed off.

Be sure to leave the cock

open until all drainage stops.

DRAIN COCK

DESCRIPTION

Drain cocks have a brass body fitted with a tapered

brass key.

The drain cock is open when the handle is

parallel to the body and closed when the handle is at

right angles to the body.

Drain cocks are installed in the bottom of each reservoir

(Fig.

1) in the air brake system to provide a convenient

means of draining the condensation which normally

collects in the reservoirs.

Always open a drain cock by hand.

Never strike the

handle with a hammer or any other instrument, as the

cock will be damaged and leakage will develop.

Back to Top