TM-5-3805-254-14-P-2 - Page 153 of 894

TRUCK SERVICE MANUAL

CHAPTER IV

MIDLAND ROSS

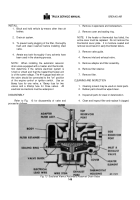

Description (Fig.

1)

The foot-operated brake valve is the main air control

device of the air brake system.

While some different

models or types may be encountered, all brake valves

are similar in construction and are operated by either a

brake treadle or pedal.

Movement of the treadle or pedal controls the

movement of an inlet and exhaust valve which controls

the air pressure delivered to or exhausted from the brake

chambers.

Full depression of the treadle or pedal results in a full

brake application, partial movement of the treadle or

pedal results in correspondingly less braking force.

At any time, the brakes may be partially released by

the driver permitting a partial return of the treadle or

pedal to release position.

The amount of force being applied to the brakes is

always proportional to pedal pressure applied by the

driver.

Operation (Fig.

1)

As the driver depresses the treadle or pedal,

pressure is exerted against the plunger which moves the

piston down to close the exhaust valve and open the inlet

valve.

This permits air pressure at the inlet port (A) to

flow past the inlet valve and out the delivery port (C) to

the brake chambers to apply the brakes.

Reservoir air pressure also passes through to a

small orifice to cavity (C).

When this pressure is equal to

the mechanical force applied by the treadle, the piston

moves up to close the inlet valve cutting off further

supply of air pressure to the brakes.

The exhaust valve

remains closed preventing any loss of air pressure.

In

this position, the brake valve is in the lap position and

instantly responsive to any movement of the treadle to

increase or decrease air pressure being delivered to the

brake chambers.

When the driver returns the treadle or pedal to its full

release position, the piston completes its upward

movement to unseat the exhaust valve.

All pressure in

the service line, not exhausted through a quick release

valve, is released through the center of the piston and

the brake valve exhaust port (B).

BRAKE VALVE

Legend for Fig. 1

Key

Description

Key

Description

1.

Body

15.

Washer, shim

2.

Plate, mounting

16.

Spring

3.

Washer, lock

17.

"O"-ring

4.

Screw, cap

18.

Piston

5.

Boot

19.

Valve, exhaust

6.

Plunger

20.

"O"-ring

7.

Ring, snap

21.

Washer, lock

8.

Guide spring

22.

Screw, cap

9.

Cleaner, air

23.

Spring, valve

10.

Cap

24.

Cap, end

10A.

Screen

25.

Valve, inlet

11.

Washer, shim

26.

Nut

12.

Spring

27.

Gasket

13.

Ring, snap

28.

Screw

14.

Seal, vee-block

Disassembly (Fig.

1)

1. Scratch mark end cap, cage, body and mounting

plate to assist in correct positioning for

assembly.

2. Remove boot (5).

3. Remove three cap screws (4), lock washers (3)

and mounting plate (2).

151

BRAKES-AIR

Back to Top