TM-5-3805-254-14-P-2 - Page 235 of 894

BRAKES-PARKING

MOTOR TRUCK SERVICE MANUAL

operating pressure limits, will result in the spring brakes

automatically applying the service brakes.

CAUTION:

DO NOT attempt to perform any

disassembly whatsoever of the parking brake with the

unit on the vehicle, even though the air pressure is

exhausted and the parking brake spring is some what

decompressed as shown in Fig.

6.

The parking brake

spring is by no means completely decompressed.

It is

still exerting a force of approximately 1200 lb.

against

the head of the chamber.

Disassembly of the parking brake should be

performed with the unit on an arbor press or hydraulic

press where adequate safety measures can be taken

(see "DISASSEMBLY").

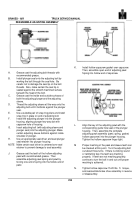

Fig.

7

Parking Brake Applied through Loss of Air

Pressure and Service Brake Released with Release Bolt.

Fig.

7 illustrates release mechanism of the spring brake.

Note position of release bolt and push rod.

REMOVAL From the information outlined under

"OPERATION", it can be readily seen that to avoid

possible serious bodily injury and damage to the brake

assembly, no attempt should be made to disassemble

the parking brake with unit installed on the vehicle.

The

parking brake should be removed from the vehicle as a

complete assembly and moved to a suitable press where

adequate safety measures can be taken during

disassembly.

The following information will assist

in the removal of the parking brake and service brake

assembly:

1. Adequately block vehicle wheels to prevent

vehicle from rolling.

2. Release air pressure to parking brake and

service brake.

3. Remove air hoses from parking brake and

service brake chambers.

Tag hoses for proper

reassembly.

4. Disconnect service brake piston rod from slack

adjuster.

5. Remove parking and service brake assembly

from mounting bracket.

DISASSEMBLY

The following disassembly procedure is based on the

parking and service brake assembly being removed from

the chassis:

1. Remove the breather cap from end of parking

brake cylinder.

This will expose the release bolt.

Back to Top