TM-5-3805-254-14-P-2 - Page 228 of 894

BRAKES - AIR

TRUCK SERVICE MANUAL

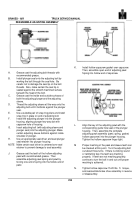

REASSEMBLE ADJUSTING ASSEMBLY

A.

Grease coat the adjusting bolt threads with

recommended grease.

B.

Install plunger seal onto the adjusting bolt by

working the bolt through the seal hole.

Be

careful not to damage the seal lip on the bolt

threads.

Also, make certain the seal lip is

seated against the smooth machined surface

beneath the head of the bolt.

C.

Grease coat the inside and outside surfaces of

both the adjusting plunger and the adjusting

sleeve.

D.

Thread the adjusting sleeve all the way onto the

adjusting bolt until it bottoms against the plunger

seal.

E.

Use a suitable pair of snap ring pliers and install

snap ring in place on end of adjusting bolt.

F.

Install the adjusting plunger into the plunger

housing, aligning plunger key-way slot with

capscrew hole of housing.

G.

Insert adjusting bolt (with adjusting sleeve and

plunger seal) into the adjusting plunger. Make

certain adjusting sleeve bottoms against inside

shoulder of plunger.

H.

Use an appropriate seal driver and seat plunger

seal retainer into plunger housing.

NOTE Make certain seal driver is centered over seal

retainer to prevent damage to seal assembly.

J.

Grease coat the teeth of the hollow adjusting

pawl with recommended grease.

Then

assemble adjusting pawl spring and pawl by

forcing one end of spring into the hollow end of

pawl.

K.

Install hollow capscrew gasket over capscrew.

Then, assemble open end of adjusting pawl

Spring into hollow end of capscrew.

L.

Align the key of the adjusting pawl with the

corresponding guide hole seat of the plunger

housing.

Then, assemble the complete

adjusting pawl assembly (pawl, spring, gasket,

hollow capscrew) into the plunger housing.

Tighten the hollow capscrew finger tight.

M

Proper meshing of the pawl and sleeve teeth can

be checked at this point.

Turn the adjusting bolt

out about three turns.

If there is clicking sound

or ratcheting feel, the teeth are meshing

properly.

If teeth are not meshing properly,

continue to turn the bolt in and out until proper

meshing is achieved.

N.

Tighten hollow capscrew 15-20 lbs.

ft.

torque,

and reassemble brake shoe assembly in reverse

of disassembly.

224

Back to Top