TM-5-3805-254-14-P-2 - Page 221 of 894

BRAKES - AIR

TRUCK SERVICE MANUAL

STOPMASTER II WEDGE BRAKE

DESIGN IMPROVEMENTS

The Stopmaster II Wedge brake now incorporates a

series of design changes based on the original

Stopmaster

brake.

Major design improvements have been made in four

general areas of the brake: (1) The automatic adjusting

assembly; (2) The adjusting pawl assembly;

(3) The

non-pressure

half of the

air chamber; and (4) The brake

shoe and drum.

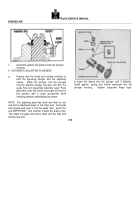

AUTOMATIC ADJUSTING BOLT ASSEMBLY

Limited Travel Adjusting Bolt

The automatic adjusting assembly for the Stopmaster II

employs a limited travel adjusting bolt which cannot over

adjust or cock when the brake lining has been extremely

worn.

This is accomplished with the addition of a snap ring at

the foot of the bolt and a redesigned adjusting sleeve

(actuator) and plunger.

The adjusting sleeve has been counterbored on the I.D.

to accept the redesigned adjusting bolt.

Thus, when the lining Is worn, the counterbored shoulder

of the adjusting sleeve stops the bolt from advancing

further.

Consequently, the bolt is prevented from over

adjusting.

To accommodate these changes, the I.D.

of the

adjusting plunger has also been counterbored to make

room for the snap ring.

WARNING

Once a condition exists of worn linings and the adjusting

bolt is totally extended, continued braking will result in a

gradual deterioration of that wheels braking ability.

Periodic inspection in accordance with the recommended

preventive maintenance is necessary to retain maximum

braking performance.

If the original adjusting sleeve (actuator) which does not

have the new counterbore (has internal threads the full

length) is to be used, do not employ the adjusting bolt

retainer (snap) ring.

Use of the retainer (snap) ring with

the old style adjusting sleeve (actuator) and new style

adjusting bolt would prevent the adjusting bolt from

moving outward and making the necessary lining wear

adjustment.

In addition, the adjusting bolt now has a machined

smooth wiping surface under the head to accept a new

single lip plunger seal.

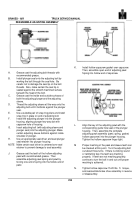

Single Lip Plunger Seal

The adjusting assembly also employs a new single lip

plunger seal to provide more protection for the bolt

threads and improved sealing for the actuation housing

components.

The lip of this seal wipes against the

smooth machined surface beneath the head of the bolt.

This seal is designed to allow more flexibility and will

provide additional protection for the adjusting assembly

when the bolt is extended outward in brake application.

Thus, this will reduce the possibility of the adjusting bolt

freezing, due to any corrosion or dirt inside the actuation

housing.

Adjusting Bolt

To protect the plunger seal, the head of the adjusting bolt

incorporates a redesigned stamped seal protector and

rolled spring lips.

The seal protector

217

Back to Top