TM-5-3805-254-14-P-2 - Page 222 of 894

BRAKES - AIR

TRUCK SERVICE MANUAL

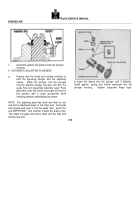

is angled downward to act as a shield over the plunger

seal.

This prevents contact between the seal and the

adjusting spoon when the brake is being adjusted

manually.

The spring lip serves to protect the plunger

seal when the bolt is in the bottomed position.

To further facilitate the initial manual adjustment, the star

wheel portion of the adjusting bolt head employs square

teeth.

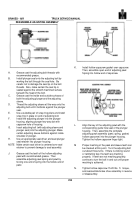

ADJUSTING PAWL ASSEMBLY

The adjusting pawl for the Stopmaster II Wedge brake

employs an integral key which mates with a slot in the

adjusting pawl guide hole of the redesigned brake spider

or actuation housing.

The keyed pawl and slotted guide hole assures correct

positioning of the pawl inside the plunger to allow the

brake to adjust automatically.

This design makes it

necessary for the keyed pawl assembly to be used only

with brake spiders and bolted on actuation housings

which employ slotted pawl guide holes.

The keyed adjusting pawl, spring and hollow capscrew

are pre-snapped together as one assembly to facilitate

reassembly of these parts into the spider and bolted on

actuation housings.

To achieve this, both the capscrew

and pawl have hollow ends, and the spring has one large

diameter coil at each end which force fits (presnaps) into

the

open

ends

of

the

pawl

and

capscrew.

The

keyed

adjusting

pawl

assembly

is

not

interchangeable with the original adjusting pawl

assembly because of the keyed pawl.

However, the

individual spring, gasket and hollow capscrew are

interchangeable with original parts.

NON-PRESSURE

HALF

ASSEMBLY

The power unit of the Stopmaster II employs a larger,

and more flexible diaphragm boot seal It also employs a

boot retainer clamp which is riveted to the wall of the

non-pressure half of the housing.

The lip of the

diaphragm boot is positioned beneath the boot retainer

clamp, and Is thus held tightly against the wall of the

nonpressure housing.

This provides improved sealing

for the air chamber tube by preventing road

contaminates from entering the wedge area and

contaminating the lubricant.

Further, the mechanical

attachment of the boot retainer clamp prevents possible

separation of the diaphragm boot from the housing.

CHAMFERED BRAKE DRUM

Other design improvements for the Stopmaster II include

a chamfer on the brake drum on the inside outer edge to

facilitate removal when brake service is necessary.

The

chamfer allows the brake lining to overlap the drum edge

by approximately 1/16".

This, in turn, prevents the

development of scored wear rings on I.D.

of the drum,

which could interfere with disassembly.

218

Back to Top