TM-5-3805-254-14-P-2 - Page 224 of 894

BRAKES - AIR

TRUCK SERVICE MANUAL

Recommended Grease

A high temperature water-proof grease IH 251 HE.P.

grease or equivalent to NLGI # 2 multi-purpose lithium

grease is recommended for lubricating the brake

actuating system.

The

following

greases

meet

all

of

these

recommendations:

Texaco Thermotex EP #1

Shell Darina #1

Marathon 528 H.D.

Sunaplex #1 EP

Amdex # 1 EP

Philube B #1

NOTE: Vehicles

operating in extremely cold weather

(below -400F) may require a grease conforming to MIL-

G-25013C.

TROUBLE SHOOTING GUIDE

If brakes are poor or do not apply

- check system

pressure at source and at brakes possible restriction or

leak in brake lines, valves, etc.

brakes out of adjustment

leaking diaphragm or wheel cylinder cup.

Uneven braking or lining wear

- ruptured diaphragm

wedge rod out of push rod socket

rollers and cage out of

plunger socket corroded or frozen plungers

brakes out

of adjustment grease on lining glazed lining shoes

installed backward combination linings.

Automatic Adjusters not working

- adjusting pawl

installed backward pawl spring collapsed or missing

bolt

frozen in adjusting sleeve detent damaged and allowing

bolt to rotate with sleeve adjusting plunger in wrong

position in the spider (should be at leading end of shoe)

double lip seals not installed correctly.

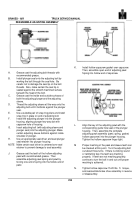

GENERAL MAINTENANCE

This section of maintenance instructions is outlined

specifically for the major design improvements of the

Stopmaster II,

BRAKE ADJUSTMENT

The following procedures can be used for the initial

manual adjustment of Stopmaster II wedge brakes.

NOTE: Since the Stopmaster II is an automatic adjusting

brake, periodic manual adjustment is not

necessary.

A

Jack or hoist wheels free of ground.

B.

Remove dust cover from adjusting slot

two

places on each brake.

NOTE:

(double actuated) type brakes the adjusting

slots are below the forward and above the rear power

unit.

Back to Top