TM-5-3805-254-14-P-2 - Page 487 of 894

TRUCK SERVICE MANUAL

FUEL SYSTEM

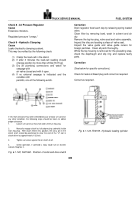

ST-790 Trouble Shooting

ST790 Trouble Shooting/Maintenance

This section of the manual should be fully understood by

the Injector Test Stand operator, and through this

knowledge he should be able to correct the test stand

problems

and

subsequently

produce

a

properly

calibrated injector.

The ST790 Injector Test Stand is the recommended

calibration equipment for Cummins injectors and was

developed to provide accurate balancing and testing of

Cummins injectors in order to produce the desired

engine performance.

Injector calibration on the ST790 Injector Test Stand

combined with fuel pump calibration on

Cummins Fuel Pump Test Stands with flow

meters has produced widespread acceptance of

fuel system accuracy.

There have been reports

of erratic results, but investigations have

revealed that the cause for such

problems fall into three basic categories.

1. Mechanic and/or Tester Error:

(Not confined to

injector calibration alone.

Includes pump

calibration, engine and chassis dynamometer

checks, etc.)

2. Instrumentation Errors:

(Range

all

way

from

gauge used on cuptoplunger seat check to load

indicator on chassis dynamometer.

3. ST790 Maintenance Status These three problem

areas are itemized as follows:

a. Mechanic and/or Tester Error

1. Calibrating a specific injector model to the wrong

flow value.

2. Calibrating a specific fuel pump model to the

wrong value.

3. Lack of familiarity with this bulletin and/or Bulletin

No. 3379068, 983505, 3379084 and No.

983533.

4. Use of wrong injector assembly in a specific

engine model.

5. Use of camshaft and pistons other than those

shown in CPL.

6. Restricted intake air to engine.

7. Excessive exhaust back pressure.

8. Restricted fuel supply to engine.

9. Aerated fuel supply to engine.

10. Excessively high oil level in engine crankcase.

b. Instrumentation Errors (Other than ST790) 1.

Erroneous fuel manifold pressure gauges on

engine and/or chassis dynamometer.

2. Erroneous flowmeters.

3. Erroneous dynamometer load indicators.

c. Neglect of ST790 Maintenance.

1. Use of hose lengths, diameters, and resiliencies

other than those which are specified.

Caution:

Do not replace any hoses or lines on the

ST790 Test Stand with other than the correct ST hose as

specified in the tool catalog.

Hoses on ST790 should be

replaced periodically since rubber in the hose hardens

with age causing resonance variables.

2. Fuel routing which is not to specifications.

3. Filter assemblies which have a different

dampening effect on the system.

4. Critical components of the test stand such as

check valve, gauge and hydraulic injector

clamping poorly maintained.

Trouble Shooting The ST790

Injector

calibration

problems

are

discovered

by

inconsistent results in service injectors or inability to flow

injectors which have been calibrated at the factory or at

other locations to the proper specifications.

When an

injector calibration

problem

is

indicated,

the

following

troubleshooting guide is to be used in the diagnosis and

correction of the problem.

All injector calibration

complaints have been found to fall into the six basic

categories as follows.

1. Stand repeatability.

Stand will not repeat

consistently on any given injector.

2. Poor results on all injector models.

Injectors do

not perform well in engine and do not correlate

with injectors calibrated on other stands.

3. NHRS, NRT injectors heavily overfueled.

PT

(type B) and PT (type D) injectors slightly

underfueled.

Reasonable results on all other

injectors.

4. All PT (type B) (type C) and PT (type D) injectors

overfueled.

Reasonable results on all other

injectors.

5. NHRS, NRT and all PT (type B) (type C) and PT

(type D) injectors overfueled.

Results are

reasonable with all other injectors.

6. All PT (type B) (type C) and PT (type D) injectors

underfueled.

482

Back to Top