TM-5-3895-371-10 - Page 25 of 103

TM 5-3895-371-10

CHAPTER 2

OPERATING INSTRUCTIONS

Section I. OPERATING PROCEDURES

2-1. Introduction.

This section will tell you how to fill, circulate, operate, and shutdown the Bituminous Distributor under ordinary operating

conditions. It identifies controls and tells you how to use them.

NOTE

See TM 9-2320-273-10 for M918 truck chassis operating instructions.

2-2. Initial Guidelines

Before you operate the distributor, you should:

a

. Perform your before (B) PMCS.

If necessary, notify Organizational Maintenance of problems.

b

. Read all safety rules and be aware of hazardous conditions.

2-3.

Controls and Indicators.

a.

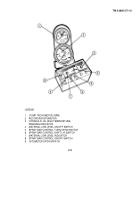

Hydraulic Controls.

The hydraulic controls (fig 2-1) provide control of the air and hydraulic systems. The

controls and their functions are:

(1) Pump Tachometer (GPM) - Accurately registers asphalt pump discharge in gallons per minute

(2) Recording Bitumeter - With the bitumeter wheel lowered and distributor in motion, provides operator with the

exact speed in feet per minute, also the number of feet traveled Bitumeter indicates from 0-1500 ft per minute

(3

) Hydraulic Oil High Temperature Warning Indicator - Light comes on when hydraulic oil reaches a temperature

above 185 degrees F.

(4)

Material Low Level On/Off Switch - Energizes the tank gage circuit to provide a visual indication to the

operator by the Material Low Level Indicator

(5) Spray Bar Control Turn Up/Dn Switch - Activates the air cylinders to raise or lower the Spray Bar

(6) Spray Bar Control Shift L/R Switch -- Activates the air cylinders which shift the spray bar left or right

2-1

Back to Top