TM-5-3895-372-10 - Page 19 of 184

TM 5-3895-372-10

CHAPTER 2

OPERATING INSTRUCTIONS

Section I. OPERATING PROCEDURES

2-1. Introduction.

This section will tell you how to load, start up, operate and shut down the mixer under ordinary conditions.

It identifies

controls and tells you how to use them. Making good concrete is easy If you follow the instructions exactly.

NOTE

See TM 9-2320-273-10 for M919 truck chassis operating instructions.

2-2. Concrete Mix Settings.

a. Mixer Set-Up.

The first thing that is required before placing a mixer in service is to perform the calculations

needed to "set-up" a mixer to produce concrete with a specified mix design, whether stated by weight or volume.

b. Mixer Calibration.

Because there are slight variations in each mixer, each unit is carefully calibrated at the factory

to determine the following factors required to calculate cement mix settings charts.

(1) Cement Meter Count This is the meter count required to discharge one cubic foot of cement into a mix.

(2) Cement Discharge Time.

This is the number of seconds required to discharge the one cubic foot of cement

into a mix.

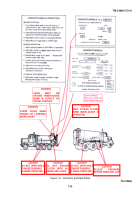

c. Calibration Data and Certification Plates.

The calibration data and certification plates (fig 2-1) are installed on

every mixer and pertain to that mixer only.

d. Mix Settings Information.

CAUTION

Every mixer needs its own mix settings chart.

Make a separate chart for each machine. Make sure

each operator uses only the chart for his machine.

2-1

Back to Top