TM-5-3895-372-20 - Page 297 of 694

TM 5-3895-372-20

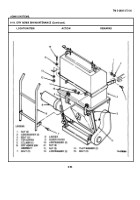

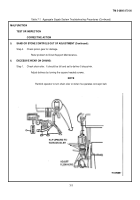

Table 7-1.

Aggregate Supply System Troubleshooting Procedures (Continued).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3.

CONVEYOR BELT IS TORN OR DAMAGED (Continued):

Step 4.

Check for 1/16 in.

(1.59 mm) clearance between metal guides,

and top of belt.

Adjust guides (para 7-10).

Step 5.

Check operation of vibrators.

Troubleshoot air system (para 11-5).

Step 6.

Check for damaged cross bars.

a.

Empty sand and stone bins.

b.

Operate belt.

Use low operating speed.

c.

As each cross bar passes inspection ports,

check for:

(1) Bends.

(2) Breaks.

(3) Twists.

(4) Looseness.

d.

Refer problem to Direct Support Maintenance.

Step 7.

Check for damaged chain.

a.

Empty sand and stone bins.

b.

Operate belt.

Use low operating speed.

c.

Check for proper lubrication of chain.

(S

ee TM 5-3895-372-10 and LO 5-3895-372-12).

d.

As each link passes sprocket at rear,

check for:

(1) Loose crossbars.

(2) Crossbars attached to wrong links.

(3) Broken links.

e

.

Refer problem to Direct Support Maintenance.

7-5

Back to Top