TM-5-3895-372-20 - Page 298 of 694

TM 5-3895-372-20

Table 7- 1.

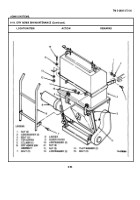

Aggregate Supply System Troubleshooting Procedures (Continued).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3.

CONVEYOR BELT IS TORN OR DAMAGED (Continued):

Step 8.

Check for bridging or arching in sand and stone bins.

Use clean aggregates for good quality.

(See TM 5-3895-372-10).

4.

SAND OR STONE DROPS ON GROUND BENEATH CONCRETE MOBILE DURING MIXING.

Step 1.

Check for 1/16 in.

(1.59 mm) clearance between metal guides and top of belt.

Adjust metal guides (para 7-10).

Step 2.

Check that rubber guides touch belt.

Adjust rubber guides (para 7-9).

Step 3.

Check that belt wiper is funneling all material into chute.

Adjust wipers (para 7-11 and 7-12).

5.

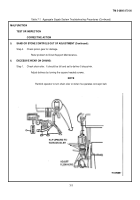

SAND OR STONE CONTROLS OUT OF ADJUSTMENT:

Step 1.

Check that drilled holes on shaft handwheels and pointer collars are aligned.

(See TM 5-3895-372-10).

a.

Loosen collar set screw.

b.

Align holes.

c.

Tighten set crew.

Step 2.

Use Gate Opening Gage to check sand and stone gate openings (See TM 5-3895-372-

10).

Gates should be open 3 in.

(76 mm) when dials read 6.4 + 0.2.

Adjust gate openings.

Step 3.

Check universal joints for:

a.

Looseness.

b.

Breakage.

c.

Alignment of drill holes.

Tighten,

align,

or replace universal joints (para 7-18).

7-6

Back to Top