TM-55-1425-289-14

TM-55-1425-289-14 - Page 34 of 61

TM 55-1425-289-14

Table 5-7.

Continued

Item

No. Required

Application

C

(cont)

and nail to the semitrailer floor through the

2- x 4- x 36-inch piece with five 20d nails in

a staggered pattern. Nail the other 2- x 4- x

36-inch piece to the one below in a like man-

ner with five 30d nails.

D

4

Chains, load-lashing.

Attach to the front and

rear tiedown provisions on the vehicles and

semitrailer as indicated. Substitute, if de-

sired, 112- or 5/8-inch IWRC wire rope in a

complete loop, and secure with four cable

clips spaced about 4 inches apart.

E

4

Load binders.

Secure grabhooks to chains,

and take up slack with eccentric takeup.

Grabhooks are not required if wire rope and

cable clips are used.

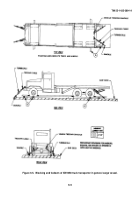

Table 5-8.

Application of Materials for Blocking and

Tiedown of an S280 Shelter, with OMTS, on

Semitrailer (Fig 5-6)

Item

No. Required

Application

A

2

End blocks. Each to consist of one piece of 4-

x 4- x 48-inch lumber.

Center and place

each piece against the end of the shelter, and

nail to the floor with eight 60d nails. Nail

the lower 2- x 4- x 48-inch piece to the 4- x

4- x 48-inch piece with eight 30d nails. Nail

the upper 2- x 4- x 48-inch piece to the low-

er piece with eight 20d nails. If the trailer or

truck is equipped with a headboard, the for-

ward end block should be placed prior to

loading the shelter on the trailer or truck.

Table 5-8.

Continued

Item

No. Required

Application

B

4

Side blocks. Each to consist of one piece of 4-

x 4- x 36-inch lumber and two pieces of 2-

x 4- x 36-inch lumber. Place the 4- x 4- x

36-inch piece on the floor and against the

shelter about 18 inches in from the end of

the shelter.

Nail to the floor with six 60d

nails. Nail the lower 2- x 4- x 36-inch piece

to the 4- x 4- x 36-inch piece with six 30d

nails.

Nail the upper 2- x 4- x 36-inch piece

to the lower 2- x 4- x 36-inch piece with six

30d nails.

C

8

Tiedowns. Each to consist of one piece of

wire rope, 3/8-inch, 6 x 19, IWRC, length as

required. Form a complete loop between the

tiedown provision and the appropriate

trailer stake pocket at a maximum angle of

450. Wire-rope ends should overlap approx-

imately 24 inches.

D

48

Clamps. Place four on each item E at the

overlapped area.

Space clamps 3-1/2 inches

apart, with a minimum of 6 inches from the

ends of the wire rope.

Place one clamp on

each thimble, item G, to secure the thimble

to the wire rope at the trailer stake pockets

and at the equipment tiedown provisions.

E

16

Thimbles. Locate one under the wire rope at

each place where the wire rope passes

through the equipment tiedown provisions

and over the edge of the trailer stake

pockets.

Secure each thimble to the wire

rope with one 3/8-inch clamp.

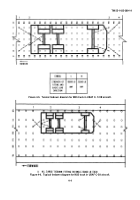

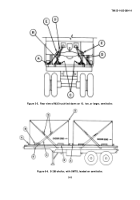

Figure 5-4.

Blocking and tiedown of M35 truck on 12-ton, or larger, semitrailer.

5-7

Back to Top