TM-55-2350-215-10-15 - Page 42 of 66

TM 55-2350-215-10-15

CHAPTER 7

RAIL TRANSPORTABILITY GUIDANCE

Section I.

GENERAL

7-1.

Scope

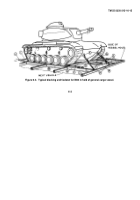

This chapter provides rail transportability guidance for

movement of the M60-series tank.

It includes technical

and physical characteristics and safety considerations

and prescribes the materials and guidance required to

prepare, load, tie down, and unload the vehicle.

7-2.

Maximum Utilization of Railcars

Additional cargo, as approved by the activity offering the

items for transport, may be transported on the same

railcar with the tank.

Section II.

TRANSPORT ON CONUS RAILWAYS

7-3.

General.

The transportability guidance contained in this section is

applicable when the vehicle is transported on CONUS

railways.

Consideration is given to single and multiple

movements for the types of flatcars normally used in the

movement of this vehicle.

The vehicle, when loaded on

a suitable flatcar, can be transported without

sectionalization or major disassembly.

The M60-series

tank exceeds width limits for unrestricted movement and

will require special routing as determined by officials of

the railroad accepting the load.

7-4.

Preparation for loading.

a.

M60-Series Tank.

Preparation of the M60-

series tank will vary among loads to be transported over

various routes on different rail equipment and with

different restraint procedures.

When tanks are moved

short distances over a single railroad line, preparation is

minimal.

When tanks are moved long distances through

interchange points of several railroad lines, preparation

must be adequate to assure safe and economic delivery

at their destination.

loading procedures are described in

paragraphs 7-5 through 7-9.

b.

Sixty-Eight Foot, 140-Ton, Chain-Tiedown

DODX Flatcar.

(1)

The 140-ton flatcar is a heavy-duty, six-

axle flatcar with a loading deck 816 inches (20.73 m)

long and 123 inches (3.12 m) wide except for the ends,

which are tapered to 117 inches (2.97 m).

Its metal

deck has four lengthwise channels holding 48 chain

tiedown assemblies.

The two outboard channels

marked A and D are 34 inches (.86 m) from the

centerline of the flatcar.

The two inboard channels

marked B and C are 239/16 inches (.60 m) from the

centerline of the flatcar.

Each channel has 44 primary

tiedown positions marked on the deck of the flatcar.

Between each marked position are four more positions;

each is 3 inches (.08 m) apart.

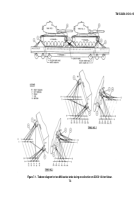

(2)

Each chain tiedown assembly is made

up of an anchor, which is movable in the channels; a

turnbuckle; a compression unit, and a 1/2-inch alloy-

steel chain, 8 feet (2.44 m) long, with an open hook on

the load attachment end and a grabhook on the

turnbuckle end.

(3)

Before loading, the chain anchors must

be locked at proper locations.

With the use of the

turnbuckle as a handle, the chain anchor must be slid

along the bottom of the channel and lifted to the

required locking location in the channel.

For the anchor

to be locked in position, the tabs at each end of the

anchor must be rotated up and moved sideways to

retract the movable pins in the anchor, and the anchor

must be lifted to completely seat in the channel notches.

This position must be held while the tabs at each end of

the chain anchor are moved sideways, to extend the

movable pins so they rest on top of the channel.

The

tabs must be rotated down and into the recess keeper.

Each turnbuckle must be extended to its mechanical

stop.

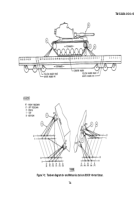

(4)

Each tiedown chain (and its fittings) to

be used be inspected for visible breaks, cracks, gouges,

open welds, or deformed components.

Special attention

must be given to the connector link that attaches the

chain to the anchor fitting.

If defects are found, the

chain or fitting must be replaced.

(a)

Flatcars manufactured by Fruit

Growers Express Company are equipped with chains

that have a sliding hook at the free end of the chain.

If

all components are free of visible damage, the eight-link

segment next to the free end of the chain must be

compared with the eight-link segment

7-1

Back to Top