TM-55-2350-215-10-15 - Page 36 of 66

TM 55-2350-215-10-15

Table 6-1.

Bill of Materials for Blocking and Tiedown of M60 in Hold of General Cargo Vessel (Fig.

6-2)

Item

Description

Approximate

quantity

Lumber

Douglas-fir, or comparable, straight-grain, free from material defects; Fed Spec

MM-L-751c:

4- x 6 in.

.........................................................................................

4

linear ft

2- x 12-in .

......................................................................................

80

linear ft

6- x 8-in .

........................................................................................

154 linear ft

Nails

Common, steel; flathead; bright or cement-coated; table Xl-b, Fed Spec FF-N-105a:

20d .

..................................................................................................................

20

40d .

..................................................................................................................

116

Wire

rope.

.....

6 x 19, IWRC; improved plow steel; preformed, regular-lay; table X, Fed Spec RR-W-

410a:

60 ft

5/8-in

Clamps.

.....

Wire-rope, "U"-bolt clips, single-grip, steel, Crosby heavy-duty, or equal; MIL-STD

16842:

16

5/8-in.

Shackles.

....

Clevis assembly suspension, bolt and nut type, large, FSN 1670-090-5354, or equal (for

4

front and rear towing and tiedown provisions).

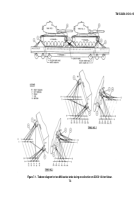

Table 6-2. Application of Materials for Blocking and Tiedown of M60 in Hold of General Cargo Vessel (Fig. 6-2)

Item

No.

Required

Application

A

4

Lumber, 2- x 12- x 240-inch.

Pre-position on vessel hold floor under vehicle treads; two

pieces required under each tread.

B

2

Side blocking.

Each consists of one piece of 6- x 8- x 240-inch lumber.

Locate against

vehicle treads; one piece on each side of vehicle.

C

2

End blocking.

Each consists of one piece of 6- x 8-in.

x length-to-suit.

Locate on top of

item B against vehicle treads.

Toenail to item B with four 40d nails at each end.

D

4

Backup cleats, 4- x 6- x 12-inch lumber.

Locate on top of item B against item C.

Toenail

to item B with four 40d nails.

E

4

Shackles.

Secure one shackle to each towing lug (two at front and two at rear end of vehicle).

F

4

Wire rope, 5/8-in., in a complete loop.

Secure with clamps (item G).

Attach to front and rear

shackles and padeyes.

G

16

Clamps, 5/8-in.

Secure to item E in complete loop.

H

4

Padeye.

Four required on floor of vessel.

J

as required

Bracing, 6- x 8in.

x length-to-suit.

Brace as required against vehicle blocking, side of vessel,

or adjacent cargo blocking to immobilize vehicle and blocking.

Secure each end to

adjacent bracing or blocking detail by toenailing with four 40d nails.

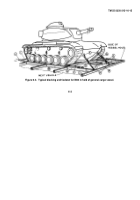

c.

Special Design

.

Seatrain trailer vessels, roll-

on/roll-off vessels, landing ships, and attack-cargo

vessels are all equipped with patented lashing gear and

pre-positioned fittings in the deck.

By proper application

of four 70,000-lb (31 752 kg) or eight 35,000-lb (15 876

kg) lashing gear to each end, the M60 will not require

blocking and bracing.

Typical application of patented

lashing gear securing M60-series tanks is shown in

figure 6-3.

6-5.

Barges and Lighters

When the vehicle is moved by barge or similar

lighterage to or from vessels secured to piers or at a

sheltered anchorage, blocking and bracing materials will

be required.

When the vehicle is moved for extended

distances or through rough waters, tiedowns must also

be used.

6-6.

Landing Ships, Landing Craft, and Amphibious

Vehicles

When the vehicle is moved for extended distances or

through rough waters, blocking and tiedowns must be

used.

In most cases, the vessels are equipped with

turnbuckles with a sheep's foot on one end that fits into

a deck cloverleaf; where turnbuckles are not provided, a

suitable substitute may be used.

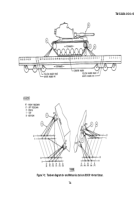

6-7.

Lighter Aboard Ship (LASH)

a.

General

.

To transport the vehicle by LASH-

type ships, securement by blocking and tiedown

requirements is essential, as illustrated in figure 6-4.

(1)

Armored tracked vehicles may arrive at

the processing area with access hatches or tank turrets

welded shut to prevent pilferage.

Since these vehicles

are not maneuverable under their

6-4

Back to Top