TM-55-2350-224-14 - Page 40 of 57

TM 55-2350-224-14

Table 4-1. Bill of Materials for Transport by Ship

Item

Quantity

Description

Shackle Assembly

4

Shackle, NSN 4030-00-279-4475. Bolt, NSN 5305-01-006-2072. Washer (2),

NSN 5310-00-809-8541. Nut (2), NSN 5310-00-891-3428, (See “Highway”

section, table 2-3, for more details.)

Chain lashing assembly, option 1

Chain

8

NSN 4010-00-803-8858, 3/8 in. x 10 ft, grade 80, 8,250-pound safe working

load.

Load Binders

8

NSN 3990-01-213-1746, type 4 latching, 9,200-pound safe working load.

When

chain

lashing not available, option 2

wire Rope

Cable clamps (clips)

1/2 in.

5/8 in.

Thimbles

1/2 in.

Chain hoist or

come-along

About 60 ft

NSN 4010-00-272-8848, 1/2-in,, impoved plow steel, 6 x 19 IWRC or

wire-strand core, nominal BS of 23,000 pounds; Federal Specification

RR-W-410.

Type I, single-saddle wire-rope, NSN 4030-00-243-4440 (1/2-in.), NSN

16

4030-00-243-4441, (5/8-in.) (Crosby heavy-duty or meet or exceed Federal Spec-

8

ification FF-C-450 requirements).

NSN 4030-00-282-2512, type III, heavy split oval construction (open pattern),

8

Federal Specification FF-T-276.

1

Adequate strength cable tensioning device.

b. Loading.

Place the carrier in the position

For the M113A and M730A2, put the transmission

indicated by the stow plan so sufficient tiedown

in SL position.

points are available. Set the parking brakes and

c.

Tiedowns.

Table 4-2 provides instructions for

place the transmission in neutral. Disconnect the

restraining the carriers against forces encountered

battery once the carrier is positioned aboard ship.

in normal marine operations.

Table

4–2.

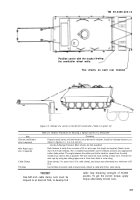

Tiedown Procedures for Securing a Carrier in the Hold of a General Cargo Ship

Item

Procedure

Chain tiedowns

Install at indicated locations. The number of chains used will depend on chain sizdstrength. Use

eight chains, NSN 4010-00-803-8858, two for each load binder. Cross two cables on the front and

rear of the carrier.

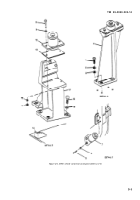

wire rope loops

Each tiedown is made from one piece of 1/2-in. wire rope. Length as required. Form a complete lmp

(4 required)

between carrier and ship tiedown provisions, The angle between the cables and deck (as viewed

horn the side) should be as close to 45° as possible. Cross cables on the fkont and rear of the car-

rier. The wire rope ends must overlap at least 24 inches. Tension the wire rope by using two cable

grippers and a 3-ton chain hoist or come-along.

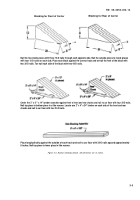

Cable clamps

Space clamps 3 3/4 in. apart as shown. Use 1/2-in. cable clamps and alternately torque nuts to a min-

imum of 65 ft-lb.

Thimbles

Use thimbles to protect cable at sharp bends. Attach to cable with %-in. cable clamp and torque

cable clamps to a minimum of 95 ft-lb.

The methods described in this chapter for

lifting and securing vehicles are recom-

mended procedures. Other methods of

handling and stowage may be used, pro-

vided they ensure safe delivery without

damage.

To develop full cable loop working

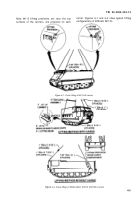

4-5. Lifting Operations

Shiploading will often require lifting the carriers

into position aboard ship. Shipside and shoreside

cranes are usually rated in long tons (LTON),

2,240 pounds, and/or metric tons (t), 1000 kilo-

grams. To lift a carrier, a crane and sling-set

capacity of at least 13 t (12.8 LTON or 28,660

pounds) is needed.

strength, 1/2-in. cable clamp nuts must be

Crane lifting operations

torqued to at least 65 ft-lb. To ensure

dangerous. Do not stand

proper torque, apply torque in stages to

both nuts alternately.

loads.

4-2

are inherently

under overhead

Back to Top