TM-55-2350-224-14 - Page 43 of 57

TM 55-2350-224-14

e.

Secure the battery.

f.

Inspect engine, brakes, and tiedowns, to en-

sure they are in good mechanical condition.

g.

Mark shipping weight and center of balance

location on both sides of the carrier.

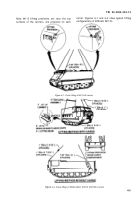

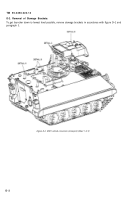

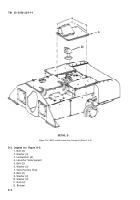

5-7-2. Specific Carrier Preparations for Airlift:

a.

M106, M106A1, and M106A2. Secure

base plate for the 107-mm mortar inside

carrier.

b. M548 and M548A1.

Secure the bows

canvas inside the carrier.

c.

M577, M577A1,

and M577A2.

Remove

antenna extensions and guards to reduce

the

the

and

the

the

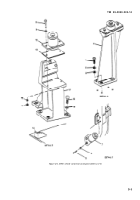

carrier to its lowest configuration. Rear ramp

requires special preparation to prevent it from

falling during transport. See appendix E for in-

structions.

d. M901, M901A1, and M981.

Reduce the

height of the carrier for transport on the C-130

and C–141 aircraft by removing the armored sight

cover from the top of the TOW launcher or

targeting head. The wide field of view (WFOV)

sight must also be removed (by a qualified fire-

control technician). Appendix D contains detailed

procedures for converting from the high stow to

the low stow position.

e.

M1068. Remove the antenna extensions and

guards, auxiliary power unit, and tent light set

mounts to reduce the carrier to its lowest configu-

ration.

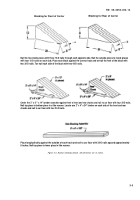

5-7-3. Loading Instructions

a.

Metal parts of the carrier tracks must not

make contact with the aircraft loading ramp or

cargo compartment floor. Prolonged operation of

vehicles causes the rubber track pads to chip,

crack, and wear, thus eliminating the rubber pad

protection and allowing the steel track shoes to

impact the surface. Therefore, the use of shoring is

always required when loading and offloading the

carriers. Use 2- by 12-inch lumber to provide two

rows of shoring 24 inches wide and spaced to

match the carrier tracks. The loaded height of the

carriers may be reduced slightly by use of 3/4inch

or 1/2-inch plywood shoring instead of 2- by 12-inch

lumber. Lay the shoring from the ground end of

the aircraft ramp extension into the cargo com-

partment, so that when the carrier is in the

tiedown position, the tracks are on the shoring.

Shoring is provided by the transported unit or by

the shipping activity.

b.

Place the transmission in neutral and set the

parking brake, after the carrier has been posi-

tioned aboard the aircraft.

c.

Restraint factors (g loads) for minimum ac-

ceptable conditions (specified for crew and passen-

ger safety in the event of a controlled emergency

landing) are specified in the applicable aircraft

Technical Orders (TO 1C-5A-9, TO 1C-130A-9,

and TO 1C-141A–9).

d.

For the M113A3 and M730A2, put the trans-

mission in SL position.

5- 2

Back to Top