TM-9-1200-215-34-P - Page 34 of 266

TM 9–1200–215–34&P

1–22

1–24.

INLET VALVE MAINTENANCE INSTRUCTIONS

DESCRIPTION

This task covers:

a.

Removal

b.

Installation

INITIAL SETUP

Tools:

Tool Kits, JTK–17LAL, TK–101/G, or TK–105/G

(items 34, 35, & 36, Appendix E)

Torque Wrench, 0–15 in.–lb (item 39, Appendix E)

7/16” x 1/4” Drive Deep Socket

(item 20, Appendix E)

Insertion and Extraction Valve Core Tool

(item 13, Appendix E)

Material/Parts:

Compound, Sealing (item 25, Appendix D)

Equipment Condition:

Unenergized LRU is on workbench.

Personnel Required:

One MOS 35Y

NOTE

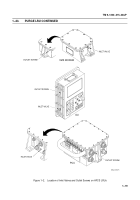

This is the standard procedure to remove the inlet valve on all LRUs.

Check table 1–1 for

approximate location of inlet valve.

Figure 1–2 provides additional detail.

Table 1–1.

Inlet Valve Locations

LRU

Location

DU

Electronic Housing

VMS Modem

Electronic Housing

PCU

Electronic Housing

a.

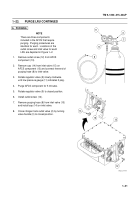

REMOVAL

1.

Remove cap (1) from valve stem (2).

2.

Using valve core tool, remove valve core (3)

from valve stem (2).

3.

Remove valve stem (2) from electronic

housing (4).

b.

INSTALLATION

1.

Apply sealing compound to valve stem (2) pipe

threads.

Insert valve stem (2) into electronic

housing or bottom cover (4), as appropriate.

2.

Torque valve stem (2) to 10 + 1 in.–lb

(1.1 + 0.1 N

S

m).

3.

Install valve core (3) in valve stem (2) and

tighten until firmly seated.

4.

Install cap (1) on valve stem (2).

Torque cap

to 4.5 + 0.5 in.–lb (0.51 + 0.06 N

S

m).

Change 1

1

4

2

3

Back to Top