TM-9-1240-401-34-P - Page 12 of 590

TM 9-1240-401-34&P

1-4. REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIR’S)

If your equipment needs improvement, let us know, send us an EIR.

ElRs will be prepared using SF Form 368 (Quality

Deficiency Report). ElRs should be mailed directly to Director, U.S. Army Armament and Chemical Acquisition and Logistics

Activity, Attn.: AMSTA-AR-QAW-A (R)/Customer Feedback Center, Rock Island, Illinois 61299-7300.

1-4.1. CORROSION PREVENTION AND CONTROL (CPC)

Corrosion Prevention and Control (CPC) of Army materiel is a continuing concern.

It is important that any corrosion problem

with this item be reported so that the problem can be corrected and improvements can be made to prevent the problem in

future items.

While corrosion is typically associated with rusting of metals, it can also include deterioration of other materials such as rubbe

and plastic. Unusual cracking, softening, swelling, or breaking of these materials may be a corrosion problem.

If a corrosion problem is identified, it can be reported using Standard Form 368, Quality Deficiency Report. Use of key words

such as “corrosion”, “rust”, “deterioration”, or “cracking” will assure that the information is identified as a CPC problem.

The form should be submitted to: Commander, U.S. Army Armament Research, Development and Engineering Center, ATTN:

AMSTA-AR-QAW-A (R) /Customer Feedback Center, Rock Island, IL 61299-7300.

Section II. Equipment Description and Data

1-5. EQUIPMENT CHARACTERISTICS, CAPABILITIES, AND FEATURES

a.

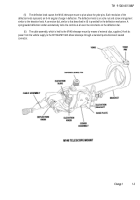

M146 Telescope Mount.

(1)

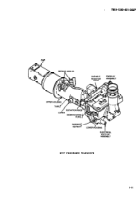

The M146 telescope mount provides an adjustable support for the M118A2/M118A3 elbow telescope. The M146

telescope mount consists of a yoke, a bracket, an elevation bracket, a base plate, an elevation knob mechanism, a deflection

knob mechanism, and a cable assembly.

(2)

The yoke and the base plate are bolted to the howitzer cradle. The yoke has a pair of machined crosskeys that fit

into corresponding slots in pads machined onto the cradle to prevent shifting of the yoke during recoil. The yoke is secured to

the bracket by two yoke pins which fit into the opposite ends of a vertical bore in the bracket. The bracket is secured to the

main bracket of the M146 telescope mount.

(3)

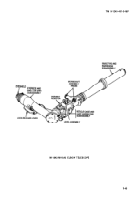

The M118A2/M118A3 elbow telescope is supported in elevation by an elevation slide which travels on an arc

about the center of the telescope ball which fits into the forward end of the bracket. A keyed ratchet on the elevation slide

engages a slot on the main bracket to brace the M118A2/M118A3 elbow telescope against recoil. Lateral movement of the

elevation knob mechanism is prevented by a retainer plate which acts as a “T” slot key. The M118A2/M118A3 elbow telescope

is held in position by a tapered (king) pin which fits into matching holes on the telescope housing.

(4)

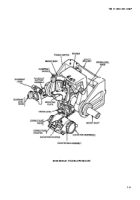

The M146 telescope mount adjusts the M118A2/M11BA3 elbow telescope for boresighting and ballistic corrections

by means of an elevation knob machined with an internal acme screw thread. Turning the elevation knob raises the elevation

slide, pivoting the M118A2/M118A3 elbow telescope vertically about the telescope ball. Elongated holes in the elevation

bracket permit an adjustment of +10 mils in elevation. Each revolution of the elevation knob represents an 8-mil angular

change in elevation, Elevation corrections are measured on a dial of angular deviations scored in tenths of a mil and numbered

1, 2, 3, 4, 5, 6, and 7 mils. A spring-loaded elevation ratchet automatically locks the controls at all even line increments on th

elevation dial.

1-2

Change 1

Back to Top