TM-9-2320-260-10 - Page 139 of 411

2-70.24

Change 4

TM 9-2320-260-10

Table 2-2. Preventive Maintenance Checks and Services (Cont’d).

ITEM

NO.

INTERVAL

ITEM TO

CHECK/

SERVICE

CREWMEMBER

PROCEDURE

NOT FULLY

MISSION

CAPABLE IF:

LOCATION

DRIVER

88

Weekly

Deepwater

a.

Tighten fuel tank filler cap(s)

a.

Requires

Fording Kit (para. 2-40).

deepwater fording

kit operation and kit

is inoperative.

b.

Ensure all battery filler caps

are present and secure (para. 2-40).

c.

Check operation of control handle.

c.

Control handle

Ensure fording valve open and

on fording valve

close (para. 2-40).

is inoperative.

UNDERHOOD CHECKS

DRIVER

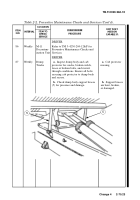

89

Monthly Surge Tank

Check all hoses (1) for deterioration

Any class III leak

and/or leakage. Tighten loose or

is evident, or hoses

leaking hose connections.

are cut or broken.

NOTE

Open and secure hood (para. 2-19).

WARNING

If temperature gauge reads above

195°F (91°C), use care when

removing surge tank filler cap.

Pressurized steam or hot coolant will

cause injury to personnel.

1

Back to Top