TM-9-2320-260-34-1 - Page 82 of 657

TM

9-2320-260-34-1

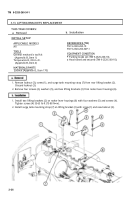

3-12. OIL COOLER MAINTENANCE

THIS TASK COVERS:

a. Removal

d. Assembly

b. Disassembly

e. Installation

c. Cleaning and Inspection

INITIAL SETUP

APPLICABLE MODELS

All

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

Engine oil cooler tester (Appendix B, Item 113)

Torque wrench, 3/8-in. dr.

(Appendix B, Item 4)

MATERIALS/PARTS

Nine lockwashers (Appendix D, Item 215)

Two gaskets (Appendix D, Item 65)

Two retaining rings (Appendix D, Item 341)

Two O-rings (Appendix D, Item 298)

Rubber bushing (Appendix D, Item 368)

Drycleaning solvent (Appendix C, Item 41)

Antiseize tape (Appendix C, Item 43)

Lubricating oil (Appendix C, Item 21)

Sealing compound (Appendix C, Item 38)

EFERENCES (TM)

TM 9-2320-260-10

TM 9-2320-260-20

TM 9-2320-260-34P-1

EQUIPMENT CONDITION

Cooling system drained (TM 9-2320-260-20).

GENERAL SAFETY INSTRUCTIONS

Keep fire extinguisher nearby when using

drycleaning solvent.

Compressed air source will not exceed 30 psi

(207 kPa).

Eyeshields must be worn when cleaning with

compressed air.

1. Remove four clamps (14), two hoses (15), and bypass tube (16) from thermostat housing (1) and oil

cooler (13).

2. Remove clamp (10) and radiator outlet hose (9) from oil cooler (13).

3. Remove clamp (12) and hose (11) from oil cooler (13).

4. Remove air compressor coolant line (2) and rubber bushing (3) from elbow (8). Discard rubber

bushing (3).

5. Remove five screws (7), lockwashers (6), oil cooler (13), and gasket (5) from cylinder block (4).

Discard lockwashers (6) and gasket (5).

1. Remove four screws (19), lockwashers (20), end cover (17), and gasket (21) from housing (25).

Discard lockwashers (20) and gasket (21).

2. Remove two retaining rings (22), O-rings (23), and element (27) from housing (25). Discard retaining

rings (22) and O-rings (23).

3. Remove elbow (8) and two plugs (18) from end cover (17).

4. Remove valve (26) and plug (24) from housing (25).

3-30

Back to Top