TM-9-2320-260-34-2 - Page 103 of 863

15-15. HOIST CYLINDER MAINTENANCE (Contd)

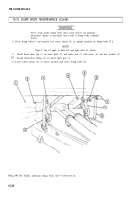

c. Cleaning and Inspection

1. For general cleaning instructions, refer to para. 2-8.

2. Inspect three check balls (2) for scratches, chips, and seat wear marks. Replace check balls (2) if

scratched, chipped, or marked.

3.

Inspect three springs (1) for wear. Replace springs (1) if spring free length is not 1.25 in. (31.75 mm).

4.

Inspect orifice plug (4) for scratches and chips. Replace orifice plug (4) if scratched or chipped.

5. Inspect cylinder housing (3), piston (5), piston rod (6), retainer (7), and cylinder head (8) for cracks,

breaks, scratches, chips, scoring, and excessive wear. Refer to table 15-1, Hoist Cylinder Wear

Limits, for measurements. Replace part(s) if damaged or worn.

Table 15-1. Hoist Cylinder Wear Limits.

ITEM

WEAR LIMITS/TOLERANCES

NO.

lTEM/POINT OF MEASUREMENT

INCHES

MILLIMETERS

3

Cylinder housing – inner diameter

5.250-5.254

133.35-133.45

5

Piston

Outer diameter

5.241-5.244

133.12-133.20

Inner diameter

1.251-1.252

31.78-31.80

6

Piston rod

Outer diameter

1.997-2.000

50.72-50.80

Inner diameter

1.249-1.250

31.72-31.75

7

Retainer

Outer diameter

2.618-2.620

66.50-66.55

Inner diameter

2.005-2.007

50,93-50.98

8

Cylinder head

Outer diameter

5.246-5.248

133.25-133.30

Inner diameter

4.770-4.774

121.16-121.26

15-42

Back to Top