TM-9-2320-260-34-2 - Page 117 of 863

TM 9-2320-260-34-2

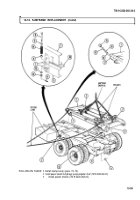

15-18. SUBFRAME REPLACEMENT

THIS TASK COVERS:

a.

Removal

b. Installation

INITIAL SETUP

APPLICABLE MODELS

M817

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

Lifting device

Two chains

Two guide lines

REFERENCES (TM]

TM 9-2320-260-20

TM 9-2320-260-34P-2

EQUIPMENT CONDITION

●

Dump body removed (para. 15-13).

●

Power takeoff-to-hydraulic pump propeller shaft

removed (TM 9-2320-260-20).

●

Splash shields removed (TM 9-2320-260-20).

MATERIALS/PARTS

GENERAL SAFETY INSTRUCTIONS

Four cotter pins (Appendix D, Item 20)

●

All personnel must stand clear during lifting

Eight locknuts (Appendix D, Item 173)

operations.

●

Ensure lifting capacity is greater than weight of

subframe.

1,

Remove eight locknuts (4) and screws (6) from subframe mounting plate (3) and frame (5). Discard

locknuts (4).

2.

Remove four cotter pins (11) from nuts (12) and screws (8). Discard cotter pins (11).

3. Remove four nuts (12), washers (13), screws (8), springs (14), and eight keepers (9) from four

subframe mounting brackets (7).

4.

Attach two chains to subframe channels (2).

5. Attach lifting device to chains and raise lifting device until slack is removed from chains.

6. Attach two guide lines to subframe (1).

WARNING

All personnel must stand clear during lifting operations.

A swinging or shifting load may cause injury to personnel.

Ensure lifting capacity is greater than weight (2,700 lb

(1,226 kg)) of subframe. Failure to do so may result in injury to

personnel or damage to equipment.

NOTE

Two assistants will help with step 7.

7. Raise subframe (1) away from sill (10) and frame (5) and position on supports.

8. Remove two guide lines from subframe (1).

9. Remove chains from subframe channels (2) and lifting device.

10.

Remove plug (15), gage (19), spacer (16), and screen (18) from tiller (17) and subframe (1).

15-56

Back to Top