TM-9-2320-260-34-2 - Page 581 of 863

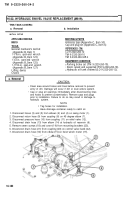

16-32. HYDRAULIC SWIVEL VALVE REPLACEMENT (M819)

THIS TASK COVERS:

a. Removal

b. Installation

INITIAL SETUP

APPLICABLE MODELS

M819

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

1-1/16-in. open-end wrench

(Appendix B, Item 123)

1-1/2-in. open-end wrench

(Appendix B, Item 125)

1-11/16-in. open-end wrench

(Appendix B, Item 127)

Lifting device

Chains

MATERIALS/PARTS

Antiseize tape (Appendix C, Item 50)

Cap and plug set (Appendix C, Item 6)

REFERENCES (TM)

LO 9-2320-260-12

TM 9-2320-260-10

TM 9-2320-260-34P-2

EQUIPMENT CONDITION

●

Parking brake set (TM 9-2320-260-10).

•

Boom raised and supported (TM 9-2320-260-10).

●

Hydraulic oil tank drained (LO 9-2320-260-12).

CAUTION

• Clean area around hoses and lines before removal to prevent

entry of dirt. Damage will occur if dirt or dust enters system.

• Cap or plug all openings immediately after disconnecting lines

and hoses to prevent contamination. Remove caps and plugs

prior to installation. Failure to do so may result in damage to

hydraulic system.

NOTE

l Tag hoses for installation.

. Have drainage container ready to catch oil.

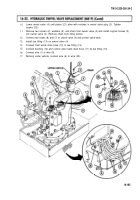

1. Disconnect hoses (3) and (5) from elbows (2) and (4) on swing motor (1).

2. Disconnect return hose (9) from coupling (8) on 45 degree elbow (7).

3. Disconnect pressure hose (10) from coupling (11) on relief valve (12).

4. Disconnect drain hose (13) from elbow (14) at hydraulic oil reservoir (6).

5. Remove seven screws

(18) and cover (19) from mounting brackets (23).

6. Disconnect drain hose (21) from coupling (20) on control valve bank (22).

7. Disconnect drain hose (16) from elbow (15) on hoist winch motor (17).

16-182

TM 9-2320-260-34-2

Back to Top