TM-9-2320-260-34-2 - Page 765 of 863

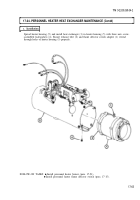

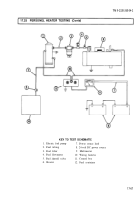

17-24. PERSONNEL HEATER HEAT EXCHANGER MAINTENANCE

THIS TASK COVERS:

a. Removal

c. Installation

b. Cleaning and Inspection

INITIAL SETUP

APPLICABLE MODELS

All

TEST EQUIPMENT

Multimeter (Appendix B, Item 115)

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

Tool kit, electrical (Appendix B, Item 106)

MATERIALS/PARTS

Three screw-assembled lockwashers

(Appendix D, Item 380)

Drycleaning solvent (Appendix C, Item 46)

Rag (Appendix C, Item 32)

REFERENCES (TM)

TM 9-2320-260-34P-2

EQUIPMENT CONDITION

●

Personnel heater flame detector switch removed

(para. 17-15).

●

Personnel heater burner removed (para. 17-21).

GENERAL SAFETY INSTRUCTIONS

●

Keep fire extinguisher nearby when working with

drycleaning solvent.

●

Compressed air source will not exceed 30 psi

(207 kpa).

●

Eyeshields must be worn when cleaning with

compressed air.

NOTE

The heat exchanger is replaced the same for early and late model

heaters. This procedure covers the early model heater.

1. Remove three screw-assembled lockwashers (4) from heater housing (5). Discard screw-assembled

lockwashers (4).

2. Separate heater housing (5) and remove heat exchanger (3).

b. Cleaning and Inspection

WARNING

●

Drycleaning solvent is flammable and will not be used near open

flame. Use only in well-ventilated places. Failure to do so may

result in injury to personnel.

●

Compressed air source will not exceed 30 psi (207 kPa). When

cleaning with compressed air, eyeshields must be worn. Failure

to wear eyeshields may result in injury to personnel,

1. Clean heat exchanger (3) and inside bore of heater housing (5) with drycleaning solvent and rag.

Dry with compressed air.

2. Inspect heat exchanger (3) for bends, cracks, stripped threads, and scoring. Repair stripped threads

if damaged. Replace heat exchanger (3) if bent, cracked, or scored.

17-64

TM 9-2320-260-34-2

Back to Top