TM-9-2320-260-34-2 - Page 89 of 863

TM 9-2320-260-34-2

15-13. DUMP BODY MAINTENANCE

THIS TASK COVERS:

a.

Removal

c.

Installation

b. Cleaning, Inspection, and Repair

INITIAL SETUP

APPLICABLE MODELS

M817

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

Lifting device

Two chains

Guide lines

MATERIALS/PARTS

Twelve

locknuts (Appendix D, Item 173)

Two locknuts (Appendix D, Item 175)

Two locknuts (Appendix D, Item 199)

PERSONNEL REQUIRED

Two

REFERENCES (TM)

LO 9-2320-260-12

TM 9-237

TM 9-2320-260-10

TM 9-2320-260-20

TM 9-2320-260-34P-2

TM 43-0139

EQUIPMENT CONDITION

●

Parking brake set (TM 9-2320-260-10).

●

Wheels chocked (TM 9-2320-260-10).

●

Remove cab protector shield (para.

15-12).

GENERAL SAFETY INSTRUCTIONS

●

Position safety braces before working under raised

dump body.

●

Do not operate dump controls

when dump body is

removed.

●

All personnel must stand clear during lifting

operations.

●

Ensure lifting capacity is greater than weight of

dump body.

I

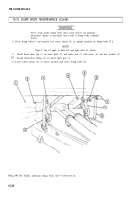

a. Removal

WARNING

Never work under raised dump body until safety braces are

properly positioned, Injury to personnel may result if dump

body

suddenly lowers.

1.

Raise dump body (2) and position two safety braces

(1)

in upright position,

NOTE

Step

2 must be performed for right and left sides of vehicle.

2.

Remove screw (5), locknut (3), and lubrication fitting (6) from thrust plate pin (4). Discard

locknut (3).

3. Lower

safety braces (1) to lowest position and lower dump body (2).

4. Attach two chains to dump body (2) and lifting device.

5. Raise lifting device until slack is removed from chains.

15-28

Back to Top