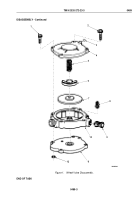

TM-9-2320-272-23-3 - Page 1091 of 1469

REMOVAL

WARNING

Air system components are subject to high pressure. Always relieve pressure before

loosening or removing air system components. Failure to comply may result in injury or death

to personnel.

1.

Remove cap (Figure 1, Item 2) and valve stem (Figure 1, Item 3) from tank valve (Figure 1, Item 5), and allow

tire (Figure 1, Item 18) to deflate completely. Install valve stem and cap on tank valve.

2.

Remove two locknuts (Figure 1, Item 27), washers (Figure 1, Item 26), screws (Figure 1, Item 28), washers

(Figure 1, Item 29), shield (Figure 1, Item 1), and spacer (Figure 1, Item 25) from studs (Figure 1, Item 16) and

axle flange (Figure 1, Item 20). Discard locknuts.

3.

Remove hose (Figure 1, Item 15) from elbow (Figure 1, Item 7) and turret valve (Figure 1, Item 17).

4.

Loosen nut (Figure 1, Item 14) and remove air manifold (Figure 1, Item 22) from wheel valve

(Figure

1,

Item

4).

5.

Remove screw (Figure 1, Item 24), washer (Figure 1, Item 23), air manifold (Figure 1, Item 22), and o-ring

(Figure 1, Item 21) from axle flange (Figure 1, Item 20) and air tube (Figure 1, Item 19). Discard o-ring.

6.

Remove two locknuts (Figure 1, Item 8), washers (Figure 1, Item 9), washers (Figure 1, Item 10), and wheel

valve (Figure 1, Item 4) from studs (Figure 1, Item 16). Discard locknuts.

7.

Remove three locknuts (Figure 1, Item 13), lockwashers (Figure 1, Item 12), and bracket (Figure 1, Item 11)

from wheel valve (Figure 1, Item 4). Discard locknuts and lockwashers.

NOTE

For repair of wheel valves, refer to (WP

0393).

8.

Remove elbow (Figure 1, Item 7) and o-ring (Figure 1, Item 6) from wheel valve (Figure 1, Item 4).

Discard

o-ring.

TM 9-2320-272-23-3

0490

0490-2

Back to Top