TM-9-2320-272-23-3 - Page 1414 of 1469

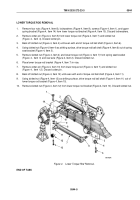

SETTING PRELOAD FOR UPPER TORQUE ROD

1.

Position upper spring bracket (Figure 5, Item 6) over upper spring bracket dowel (Figure 5, Item 7).

NOTE

Perform Step (2) for all models except M936/A1/A2 model vehicles.

2.

Raise rear axle (Figure 5, Item 8) until 6 in. (15.24 cm) is obtained between bottom of frame rail

(Figure

5,

Item

5) and top of spring bracket (Figure 5, Item 6).

NOTE

Perform Step (3) for M936/A1/A2 model vehicles only.

3.

Raise rear axle (Figure 5, Item 8) until 7-1/4 in. (18.4 cm) is obtained between bottom of frame rail

(Figure

5,

Item

5) and top of spring bracket (Figure 5, Item 6).

4.

Place ball shaft (Figure 5, Item 2) on upper torque rod (Figure 5, Item 3) in upper torque rod bracket

(Figure

5,

Item

4) and install with slotted nut (Figure 5, Item 1). Finger-tighten slotted nut.

5.

Place upper torque rod (Figure 5, Item 3) with upper torque rod bracket (Figure 5, Item 4) over dowel

(Figure

5,

Item

9) on rear axle (Figure 5, Item 8) and position torque rod ball shaft (Figure 5, Item 2) in spring

bracket (Figure 5, Item 6).

NOTE

Ensure upper torque rod bracket is seated over dowel pin and ball shaft is in spring seat

bracket before alignment is made.

6.

Scribe an alignment mark from upper torque rod bracket (Figure 5, Item 4) to torque rod (Figure 5, Item 3).

7.

Remove upper torque rod (Figure 5, Item 3) and upper torque rod bracket (Figure 5, Item 4) from rear axle

(Figure 5, Item 8) and spring bracket (Figure 5, Item 6).

8.

Place upper torque rod bracket (Figure 5, Item 4) in vise (Figure 5, Item 10) with alignment marks aligned.

9.

Tighten slotted nut (Figure 5, Item 1) 350 to 400 lb-ft (475 to 542 N·m) and install cotter pin

(Figure

5,

Item

11).

TM 9-2320-272-23-3

0544

0544-7

Back to Top