TM-9-2320-272-23-3 - Page 297 of 1469

REMOVAL

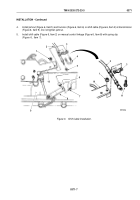

NOTE

•

The use of shim stock tube in torque converter access hole prevents converter screw

from falling down behind flywheel. A loose screw may cause a lockup condition,

preventing crankshaft rotation required to remove remaining screws.

•

Engine crankshaft may be turned using barring tool.

1.

Remove two screws (Figure 1, Item 7), access cover (Figure 1, Item 6), and gasket (Figure 1, Item 5) from

flywheel housing (Figure 1, Item 1). Discard gasket.

2.

Using engine barring tool, rotate crankshaft until screw (Figure 1, Item 4) is visible in access hole

(Figure

1,

Item 3).

3.

Roll shim stock (Figure 1, Item 3) into tube form and size to fit diameter of access hole (Figure 1, Item 2). Insert

shim stock in access hole and position over screw (Figure 1, Item 4) and against flywheel (Figure 1, Item 13).

4.

Remove remaining 12 screws (Figure 1, Item 4) from flywheel (Figure 1, Item 13) and converter

(Figure

1,

Item

12) in the same manner.

5.

Remove four screws (Figure 1, Item 8), lockwashers (Figure 1, Item 9), and clamp (Figure 1, Item 10) from 9,

11, 1, and 3 o’clock positions on flywheel housing (Figure 1, Item 1) and transmission (Figure 1, Item 11).

Discard lockwashers.

TM 9-2320-272-23-3

0372

0372-2

Back to Top