TM-9-2320-272-23-4 - Page 745 of 1393

CLEANING AND INSPECTION

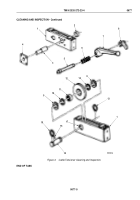

1.

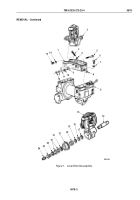

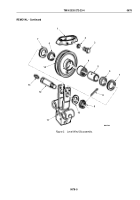

Inspect frame (Figure 3, Item 1) for breaks and cracks. Replace if broken or cracked.

2.

Clean tensioner sheave pin (Figure 3, Item 14) and inspect for pits, scoring, and wear. Replace if scored, pitted,

or if outside diameter is less than 0.9995 in. (25.39 mm).

3.

Clean sheave (Figure 3, Item 12) and inspect for breaks and cracks. Replace if broken or cracked.

4.

Clean bearing (Figure 3, Item 11) and inspect for cracks, chips, and broken cage. Replace if cracked, chipped,

broken, or if inner diameter exceeds 1.000 in. (25.4 mm).

5.

Clean two thrust washers (Figure 3, Item 9) and inspect for cracks, chips, and wear. Replace if cracked,

chipped, or if thickness is less than 0.0615 in. (1.56 mm).

6.

Clean block (Figure 3, Item 4) and inspect for cracks and elongated holes. Replace if cracked or holes

are

elongated.

7.

Clean shaft (Figure 3, Item 3) and inspect for cracks. Replace if cracked.

8.

Measure outer cam diameter of shaft (Figure 3, Item 3). Replace if cam outer diameter is less than 0.995 in.

(25.35 mm).

9.

Measure outer diameter of bearing (Figure 3, Item 11). Replace if outer diameter is less than 0.748 in.

(18.99

mm).

10.

Clean sheave (Figure 3, Item 12) and inspect for cracks and wear. Replace if cracked or broken.

11.

Clean two thrust washers (Figure 3, Item 9) and inspect for cracks and wear. Replace if cracked or if thickness

is less than 0.062 in. (1.56 mm).

12.

Clean bearing (Figure 3, Item 11) and inspect for cracks, chips, and broken cage. Replace if cracked, chipped,

or broken.

13.

Measure inner diameter of bearing (Figure 3, Item 11) and replace if inner diameter is greater than 1.000 in.

(25.4 mm).

14.

Clean two bushings (Figure 3, Item 2) and inspect for cracks, chips, and wear. Replace if cracked, chipped,

or if inner diameter exceeds 0.754 in. (19.15 mm).

15.

Clean frame (Figure 3, Item 1) and replace if damaged.

16.

Clean latch (Figure 3, Item 8) and lever (Figure 3, Item 7) and inspect for breaks and cracks. Replace if broken

or cracked.

17.

Clean poppet (Figure 3, Item 5) and inspect for bends and breaks. Replace if bent or broken.

18.

Clean spring (Figure 3, Item 6) and inspect for broken and collapsed coils. Replace if coils are broken

or

collapsed.

TM 9-2320-272-23-4

0677

0677-4

Back to Top