TM-9-2320-272-24-3 - Page 470 of 799

TM 9-2320-272-24-3

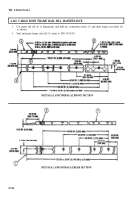

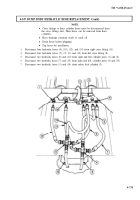

4-147. DUMP BODY HYDRAULIC HOSE REPLACEMENT

THIS TASK COVERS:

a.

Removal

b. Installation

INITIAL SETUP:

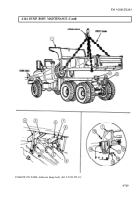

APPLICABLE MODELS

M929/A1/A2, M930/A1/A2

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

MATERIALS/PARTS

Cap and plug set (Appendix C, Item 14)

MANUAL REFERENCES (TM)

LO 9-2320-272-12

TM 9-2320-272-10

TM 9-2320-272-24P

EQUIPMENT CONDITION

l

Parking brake set (TM 9-2320-272-10).

l

Dump body in lowered position (TM 9-2320-272-10).

l

Hydraulic oil reservoir drained (LO 9-2320-272-12).

GENERAL SAFETY INSTRUCTIONS

l

Position safety braces before working under raised

dump body.

l

Ensure dump control lever is in the NEUTRAL

position and has not moved.

l

Store or dispose of used oil properly.

l

Do not remove lines when engine is running or

start engine when lines are removed.

l

Never work under dump body until safety braces are properly

positioned. Injury to personnel may result if dump body

suddenly lowers.

l

Ensure dump control lever is in the NEUTRAL position and has

not moved. Injury to personnel may result if lift cylinder is

operated when not secured.

l

Accidental or intentional introduction of liquid contaminants

into the environment is in violation of state, federal, and

military regulations. Refer to Army POL (para. 1-8) for

information concerning storage, use, and disposal of these

liquids. Failure to do so may result in injury or death.

l

Do not remove hoses with engine running or start engine with

hoses removed. High-pressure fluids may cause hoses to whip

violently and spray randomly. Doing so may result in injury to

personnel.

NOTE

All hydraulic hoses are removed the same way This procedure

covers dump hoist cylinder and safety lock hoses only.

1.

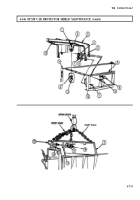

Place dump body in raised position (TM 9-2320-272-10).

2.

Place safety braces in proper position (TM 9-2320-272-10).

CAUTION

Plug all hydraulic lines or openings to prevent dirt from entering

and damaging components.

4-734

Back to Top