TM-9-2320-272-24-3 - Page 478 of 799

TM 9-2320-272-24-3

4-149. DUMP SUBFRAME REPLACEMENT

THIS TASK COVERS:

a.

Removal

b.

Installation

INITIAL SETUP:

APPLICABLE MODELS

M929/A1/A2, M930/A1/A2

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

MATERIALS/PARTS

Eight locknuts (Appendix D, Item 321)

Four cotter pins (Appendix D, Item 69)

Cap and plug set (Appendix C, Item 14)

PERSONNEL REWIRED

Three

MANUAL REFERENCES (TM)

LO 9-2320-272-12

TM 9-2320-272-10

TM 9-2320-272-24P

EQUIPMENT CONDITION

l

Parking brake set (TM 9-2320-272-10).

l

Hydraulic oil reservoir drained (LO 9-2320-272-12).

l

Dump body removed (para. 4-144).

GENERAL SAFETY INSTRUCTIONS

l

Store or dispose of used oil properly.

l

Do not remove lines when engine is running or

start engine when lines are removed.

l

All personnel must stand clear during lifting

operations.

WARNING

l

Accidental or intentional introduction of liquid contaminants

into the environment is in violation of state, federal, and

military regulations. Refer to Army POL (para. 1-8) for

information concerning storage, use, and disposal of these

liquids. Failure to do so may result in injury or death.

l

Do not remove hoses with engine running or start engine with

hoses removed. High-pressure fluids may cause hoses to whip

violently and spray randomly. Doing so may result in injury to

personnel.

CAUTION

Plug all hydraulic lines or openings to prevent dirt from entering

and damaging components.

NOTE

l

Have container ready to catch oil from hydraulic tubes, lines,

and hoses.

l

Drain hoses before plugging.

l

Tag hoses for installation.

1.

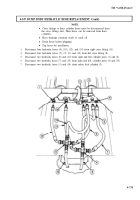

Disconnect pump-to-reservoir hydraulic tube (2) from pump adapter (3) and reservoir adapter (1).

2.

Disconnect filter-to-reservoir hydraulic hose (5) from filter elbow (4) and reservoir adapter (6).

4-742

Back to Top