TM-9-2320-273-10 - Page 218 of 452

OPERATING WINCH (M916 AND M920)

WARNING

Hearing protection is required during winching operations.

Failure to comply may result in damage to hearing. Seek

medical attention in the event of injury.

Always wear heavy gloves when handling the winch wire

rope. Never allow the cable to run through your hands as

broken wires can cause painful injuries. Failure to comply

may result in injury to personnel. Seek medical attention in

the event of an injury.

CAUTION

Do not pull up on control lever 2. This position is for

operating equipment not used on the M915 series vehicles.

Failure to comply may result in damage to equipment.

Observe drum to ensure wire rope is not completely paid

out. Never operate winch with less than four turns of line on

drum. Failure to comply may result in damage to equipment.

NOTE

The rated winch pull is set by limiting the hydraulic system

relief valve pressure to a maximum of 2,100 psi which

provides 45,000 lb (20,250 kg) pull on the bare drum. As the

winch drum is loaded with line, the effective line pull is

reduced. The line pull per cable layer with 7/8 inch wire

rope is:

1st layer 45,000 lb (20,250 kg)

2nd layer 39,265 lb (17,810 kg)

3rd layer 34,775 lb (15,773 kg)

4th layer 31,210 lb (14,156 kg)

5th layer 28,310 lb (12,841 kg)

Loading procedures will vary depending on the size and type

of equipment to be transported.

The winch speed is normal in low speed. High speed is

recommended for paying line out or taking up slack only.

1. Lower pusher axle.

2. Have crew member disconnect the wire rope clevis from its anchor.

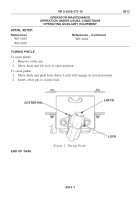

3. Pull up on winch control lever 2 to the middle position.

4. To pay out the line, pull up and hold winch control lever 1 in full up position.

The winch will unwind in low speed. Have crew member walk end of the wire

rope out.

TM 9-2320-273-10

0012

0012-20

Back to Top