TM-9-2320-279-20-2 - Page 311 of 938

TM 9-2320-279-20-2

Wheel Maintenance Instructions (Cont)

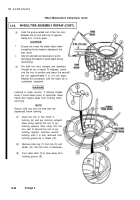

12-6.

WHEEL/TIRE ASSEMBLY REPAIR (CONT).

b.

Cleaning/Inspection.

(1)

Inspect tire tread for nails, glass and other foreign objects and for irregular wear, cuts and

blisters.

(2)

Inspect bead of tire for damaged rim seal ridges.

(3)

Inspect complete inside surface of inner tire liner for imperfections, discoloration or irregular

surface that may indicate excessive heat, breaks or other fabric damage.

(4)

Do not use a lockring or side ring if they are bent, distorted, cracked or heavily corroded.

Destroy all damaged parts.

(5)

Check rim for cracks, dents, dirt and rust, especially in the lockring groove. Clean rust and dirt

from rim using a wire brush, especially from the lockring groove to ensure proper seating.

(6)

Remove rust, gummy rubber deposits, nicks

and gouges in the rim bead seat surfaces.

(7)

Inspect inner tube and flap for cuts, pinch

marks, punctures or deterioration. Check

valve stem for damage.

(8)

Paint wheel assembly parts as needed to

protect against rust

c. Assembly.

NOTE

Always use a new tube and new flap when a new

tire is being installed.

(1)

Install rubber seal (13) and valve stem (3) on

inner tube (12).

(2)

Install valve core (4) in valve stem (3).

(3)

Install inner tube (12) in tire (5) with valve

stem (3) pointing downward.

(4)

Inflate inner tube (12) to just round out

against side of tire (5).

(5)

Lubricate flap (11) with tire lubricant and

position over valve stem (3) and between

bottom part of inner tube (12) and bottom

part of tire (5).

(6)

Install flap (11) between top of inner

tube (12) and top of tire (5).

12-28

Change 2

Back to Top