TM-9-2320-279-20-2 - Page 315 of 938

TM 9-2320-279-20-2

Wheel Maintenance Instructions (Cont)

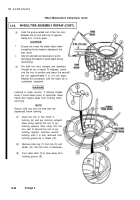

12-6.

WHEEL/TIRE ASSEMBLY REPAIR (CONT).

WARNING

Improperly seated lockrings or side rings may blow

off at any time. Never attempt to seat a lockring or

side ring during or after inflation. Failure to

comply may result in serious injury or death.

(18)

Repeat steps

(14)

and

(15).

WARNING

Never inflate tires over 40 psi (276 kPa) to seat tire

beads. If beads do not seat, deflate, demount, and

check the tire/rim parts. Relubricate and remount

tire. Serious injury or death could result if these

procedures are not followed.

(19)

If wheel/tire assembly (1) is properly

assembled, continue to inflate to 20 psi

(138 kPa) until beads seat with no gap

between tire and rim parts.

NOTE

Inflating, then deflating wheel/tire assembly will

remove wrinkles from tube.

(20)

Continue to inflate wheel/tire assembly (1)

to 100 psi (690 kPa), and check that all rim

components are properly seated, then allow

tire to deflate completely.

(21)

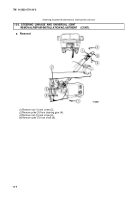

Install valve core (4) into valve stem (3).

(22)

Inflate wheel/tire assembly (1) to 100 psi

(690 kPa).

WARNING

If gap in lockring is greater than 318 in. (9.5 mm),

deflate wheel/tire assembly by removing valve

core, then replace lockring, or serious injury or

death to personnel may result. Destroy defective

lockring so it cannot be reused.

(23)

Check that gap between ends of lockring (6)

is no more than 318 in. (9.5 mm).

(24)

Install cap (2) onto valve stem (3).

(25)

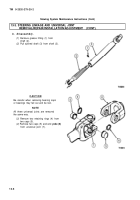

Remove wheel/tire assembly (1) from safety

cage.

d. Follow-on Maintenance.

Install wheel/tire

assembly on truck (TM 9-2320-279-10).

END OF TASK

12-32

Change 2

Back to Top