TM-9-2320-279-34-2 - Page 19 of 632

TM 9-2320-279-34-2

Axles No. 3 and No. 4 Maintenance Instructions (Cont)

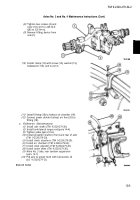

10-2.1. AXLE NO. 3 (AXLE MODEL 650) REMOVAL/iNSTALLATION (M984E1) (CONT).

b. Insallation.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(lo)

(11)

(12)

(13)

10-6.2

TA476436

WARNING

Axle is very heavy, Keep out from under heavy parts. Falling parts can cause

serious injury or death.

Soldier A and Soldier B position axle (1) on suitable lifting device.

Solider A and Soldier B install axle (1) and aline holes in each axle beam hanger bracket (2) with

holes in equalizer beam (3).

Install torque rod (4) on axle mounting bracket (5).

Lubricate two screws (6) with oil and install screws, four washers (7), and two locknuts (8).

Tighten locknuts to 460 lb-ft (624 N•m).

Tighten two locknuts (9) to 460 lb-ft (624 N•m).

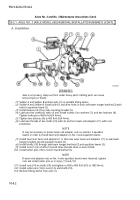

Lubricate threads of two shafts (10) with oil and four beam end adapters (11) with rust

preventive.

NOTE

It may be necessary to loosen beam end adapter nuts on axle No. 4 equalizer

beams in order to install beam end adapters in No. 3 axle equalizer beams.

Install two inner beam end adapters (11), then two outer beam end adapters (11) in axle beam

hanger brackets (2) and equalizer beams (3).

Install shafts (10) through axle beam hanger brackets (2) and equalizer beams (3).

Install nuts (12) on shafts (10) until three threads show on end of shaft.

Install cotter pins (13) in nuts (12) and shafts (10).

NOTE

If beam end adapter nuts on No. 4 axle equalizer beams were loosened, tighten

nuts and install cotter pins as in steps

(11)

and

(12).

Install nuts (14) on shafts (10) and tighten to 600 to 800 lb-ft (815 to 1085 N•m).

Install cotter pins (15) in nuts (14), and shafts (10).

Remove lifting device from axle (1).

Back to Top