TM-9-2320-280-20-2 - Page 195 of 951

4-3. ALTERNATOR PULLEY REPLACEMENT

This task covers:

a. Removal

b. Installation

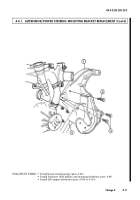

a. Removal

1.

Clamp alternator pulley (2) in a soft-jawed vise.

2.

Remove locknut (4) and washer (3) from alternator shaft (6). Discard locknut (4).

3.

Remove alternator (1) and pulley (2) from soft-jawed vise.

4.

Using a mechanical puller, remove pulley (2) and woodruff key (5) from alternator (1). Discard

woodruff key (5).

NOTE

The removal and installation procedure for 60 amp, 100 amp, and

200 amp alternator pulleys are identical.

INITIAL SETUP:

Tools

General mechanic’s tool kit:

automotive (Appendix B, Item 1)

Mechanical puller (Appendix B, Item 167)

Vise inserts (Appendix B, Item 170)

Materials/Parts

Locknut (Appendix G, Item 73)

(60, 100 amp only)

Woodruff key (Appendix G, Item 321)

(60, 100 amp only)

Locknut (Appendix G, Item 73.1)

(200 amp - Niehoff)

Woodruff key (Appendix G, Item 322)

(200 amp - Niehoff)

Manual References

TM 9-2320-280-24P

Equipment Condition

• 60 amp alternator removed (para. 4-2).

• 100 amp alternator removed (para. 12-23 or

12-24).

• 200 amp alternator removed (para. 4-109 or

4-110).

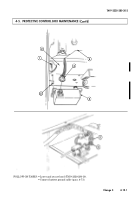

b. Installation

1.

Position woodruff key (5) in alternator shaft (6) with flat side up.

2.

Align pulley keyway (7) with woodruff key (5) in alternator shaft (6) and tap pulley (2) onto

shaft (6).

3.

Install washer (3) and locknut (4) on shaft (6). Tighten locknut (4) finger-tight.

4.

Clamp pulley (2) in soft-jawed vise.

NOTE

For 200 amp alternators (12447109 or 12338796-1), tighten

locknut to 115-125 lb-ft (156-169 N

•

m).

5.

Tighten locknut (4) to 95 ± 5 lb-ft (129 ± 7 N

•

m).

6.

Remove pulley (2) and alternator (1) from vise.

TM 9-2320-280-20-2

4-8

Change 3

Back to Top