TM-9-2320-280-20-2 - Page 696 of 951

6-29. LOWER CONTROL ARM REPLACEMENT

This task covers:

a. Removal

b. Installation

INITIAL SETUP:

Tools

General mechanic’s tool kit:

automotive (Appendix B, Item 1)

Materials/Parts

Four locknuts (Appendix G, Item 128)

(Basic/A1 Series)

Four locknuts (Appendix G, Item 105) (A2 Series)

Two locknuts (Appendix G, Item 89)

Sealing compound (Appendix C, Item 40)

Personnel Required

One mechanic

One assistant

Manual References

TM 9-2320-280-24P

Equipment Condition

• Wheel removed (para. 8-3).

• Shock absorber removed (para. 6-31).

General Safety Instructions

Lower control arm must be supported during

removal and installation.

TM 9-2320-280-20-2

6-64

Change 3

NOTE

The procedures for removing and installing the front and rear

lower control arms are basically the same. This procedure covers

the left front lower control arm.

WARNING

Lower control arm must be supported during removal and

installation. Failure to support lower control arm may cause

injury to personnel or damage to equipment.

NOTE

Note direction of outer capscrews for installation.

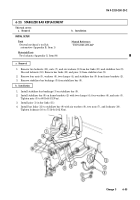

1.

Remove four locknuts (7), washers (6), capscrews (9), and washers (6) from lower ball joint (5),

geared hub (4) and lower control arm (8). Discard locknuts (7).

2.

Remove capscrew (14), two washers (12), and bar link (13) from lower control arm (8).

3.

Raise and support lower control arm (8) and pull geared hub (4) away.

4.

Lower the lower control arm (8) and remove coil spring (10).

5.

Remove two locknuts (3), washers (2), capscrews (1), washers (2), and lower control arm (8) from

brackets (11). Discard locknuts (3).

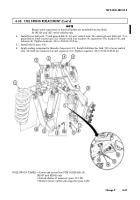

NOTE

On lower control arms, capscrew heads are toward front of

vehicle.

1.

Install lower control arm (8) on brackets (11) with two washers (2), capscrews (1), washers (2), and

locknuts (3).

2.

Install coil spring (10) on lower control arm (8) ensuring end of coil spring (10) fits in spring pocket

of lower control arm (8).

WARNING

Lower control arm must be supported during removal and

installation. Failure to support lower control arm may cause

injury to personnel or damage to equipment.

3.

Raise lower control arm (8) to align with geared hub (4) and ball joint (5) ensuring lower ball

joint (5) is placed below lower control arm (8).

b. Installation

a. Removal

Back to Top