TM-9-2320-280-34 - Page 273 of 1258

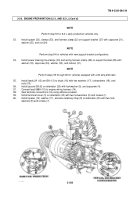

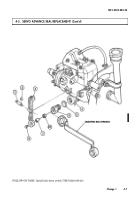

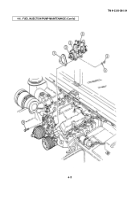

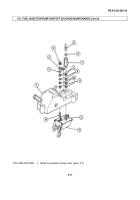

4 - 6 . FUEL INJECTION PUMP MAINTENANCE

This task covers:

a.

Removal

c.

Installation

b.

Repair

TM 9-2320-280-34

4 - 8

Change 1

NOT E

• In some cases, flanged head fasteners may be present instead of

standard fasteners and washers. In all cases, washers should be used

when replacing a flanged head fastener with a standard fastener.

• Prior to removal, tag leads for installation.

• Have drainage container available to catch fuel.

1.

Disconnect leads 54A (3) and 569B (4) at fuel injection pump (7).

1.1. Remove tiedown strap (3.1) from leads 54A (3) and 569B (4).

Discard tiedown strap (3.1).

2.

Loosen clamp (2) and disconnect fuel drain back hose (1) from fuel injection pump (7).

3.

Loosen clamp (9) and disconnect outlet hose (10) from hose adapter (8).

4.

Remove return spring (5) from throttle shaft lever (6).

5.

Pull off cable clip (12) from modulator link pin (13).

6.

Slide modulator link (11) forward and disconnect from fuel injection pump (7).

7.

Remove hose adapter (8) from fuel injection pump (7).

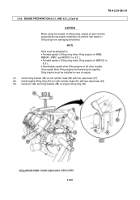

WARNING

• Diesel fuel is highly flammable. Do not perform this procedure

near fire, flames, or sparks. Severe injury or death will result.

• Gaskets installed on some 6.2L engines assembled prior to 1991

may contain asbestos. Gaskets should be removed with a

scraper or putty knife then disposed of IAW current directives.

Inhalation of asbestos fibers can cause respiratory ailments

CAUTION

Cover or plug all hoses, connections, and openings immediately

after disconnection or component removal to prevent

contamination. Remove all plugs prior to connection.

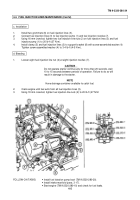

NOTE

The fuel injection pump replacement procedures for 6.2L and 6.5L

engine models prior to, and later than 1990 are basically the same. Refer

to engine decal model number on left rocker arm cover before ordering

replacement parts, since replacement parts are not interchangeable.

INITIAL SETUP:

To o l s

____

General mechanic's tool kit:

automotive (Appendix G, Item 1)

M a t e r i a l s / P a rt s

_____________

Gasket (Appendix E, Item 15)

Tiedown strap (Appendix E, Item 210.1)

Manual Refere n c e s

________________

TM 9-2320-280-10

TM 9-2320-280-20

TM 9-2815-237-34P

TM 9-2815-237-34

Equipment Condition

_________________

• Engine oil filler tube removed (TM 9 - 2 3 2 0 - 2 8 0 - 2 0 )

.

• Kick-down switch removed (TM 9-2320-280-20).

• Fuel injection lines removed (para. 4-4).

• Accelerator cable mounting bracket removed

(para. 4-10).

• Remove TP sensor (TM 9-2320-280-20).

General Safety Instructions

______________________

• Do not perform this procedure near fire, flames,

or sparks.

• Gaskets installed on some 6.2L engines assembled

prior to 1991 may contain asbestos.

Gaskets

should be disposed of IAW current directives.

Maintenance Level

_______________

Direct support

a. Removal

Back to Top