TM-9-2320-280-34 - Page 690 of 1258

1 4 - 1 7 . AIR-CONDITIONING SYSTEM SERVICING (Cont'd)

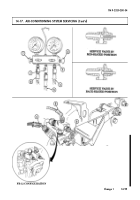

1.

Turn high pressure gauge valve (2) and low pressure gauge valve (1) on gauge set (3) clockwise to

their front-seated (closed) positions.

2.

Remove two dust caps (9) from service valves (6) and (7).

3.

Ensure both service valve shafts (11) are moved fully counterclockwise until in back-seated position.

4.

Remove two cap nuts (8) from service valve ports (10) and (12).

________

WARNING

________

Make sure hand valves on manifold gauge set are in closed position

during connection, and hoses are clear of any moving parts in

engine compartment. Injury to personnel or damage to equipment

may result.

5.

Connect low pressure gauge hose (5) on manifold gauge set (3) to suction (low side) service valve

port (10).

6.

Connect high pressure gauge hose (4) on manifold gauge set (3) to discharge (high side) service

valve (6).

7.

Hang manifold gauge set (3) so that hoses (5) and (4) are well away from moving engine parts.

NO T E

• Service valve mid-seated position is used for discharging,

flushing, evacuating, charging, and testing.

• Do not perform step 9 if system is already evacuated. High and

low pressure hoses must be purged with FR-12 or R-12 for

charging purposes (refer to task f.)

8.

Turn both service valve shafts (11) to mid-seated position.

9.

Loosen low pressure gauge hose (5) and high pressure gauge hose (4) at manifold gauge set slightly

for a second to purge air from hoses, and then tighten.

a. Manifold Gauge Set Installation

NO T E

Whenever any air-conditioning vapor system component needs

replacement, the system must be discharged, flushed, and a new

dryer bottle installed (para. 14-19).

TM 9-2320-280-34

1 4 - 9 0

Change 1

Back to Top